¡Estamos traduciendo nuestra tienda online al español!

Pero como tenemos muchos productos y páginas, esto lleva tiempo. Mientras tanto, nuestro catálogo de productos estará en inglés. Gracias por su paciencia.

Confirmado

100%

- Main Body/Related Products

- Structure

- Adjustable Type

- Stroke (mm)

- 8

- Nominal Mounting Screw [M]

- 10

- Energy per Cycle (J)

- 1.8

- Orifice Method

- Operating Environment

- Main Body Material

- Full length A (mm)

- 65.5

- Maximum Effective Weight Value (kgf)

- 10

- Type

- CAD

- 2D

- 3D

- Días estimados de envío

- Todo

- En el plazo de 7 días laborables

ACE Miniature Shock Absorbers self-adjusting

- Precio unitario (IVA no incluidos)

- 145.28 €

- Total (IVA no incluidos)

- 145.28 €Precio IVA incluidos:172.88 €

- Días previstos de envío

- 7 días laborablesFecha de envío de referencia: 21.10.2025

| Cantidad | 1 - 9 | 10 | 11+ |

|---|---|---|---|

| Precio unitario (IVA no incluidos) (Precio unitario IVA incluidos) | 145.28 € ( 172.88 € ) | 134.11 € ( 159.59 € ) | 134.11 € ( 159.59 € ) |

| Días de envío | 7 días | 7 días |

- * Información sobre días de envío, gastos de envío y precios

Información del producto

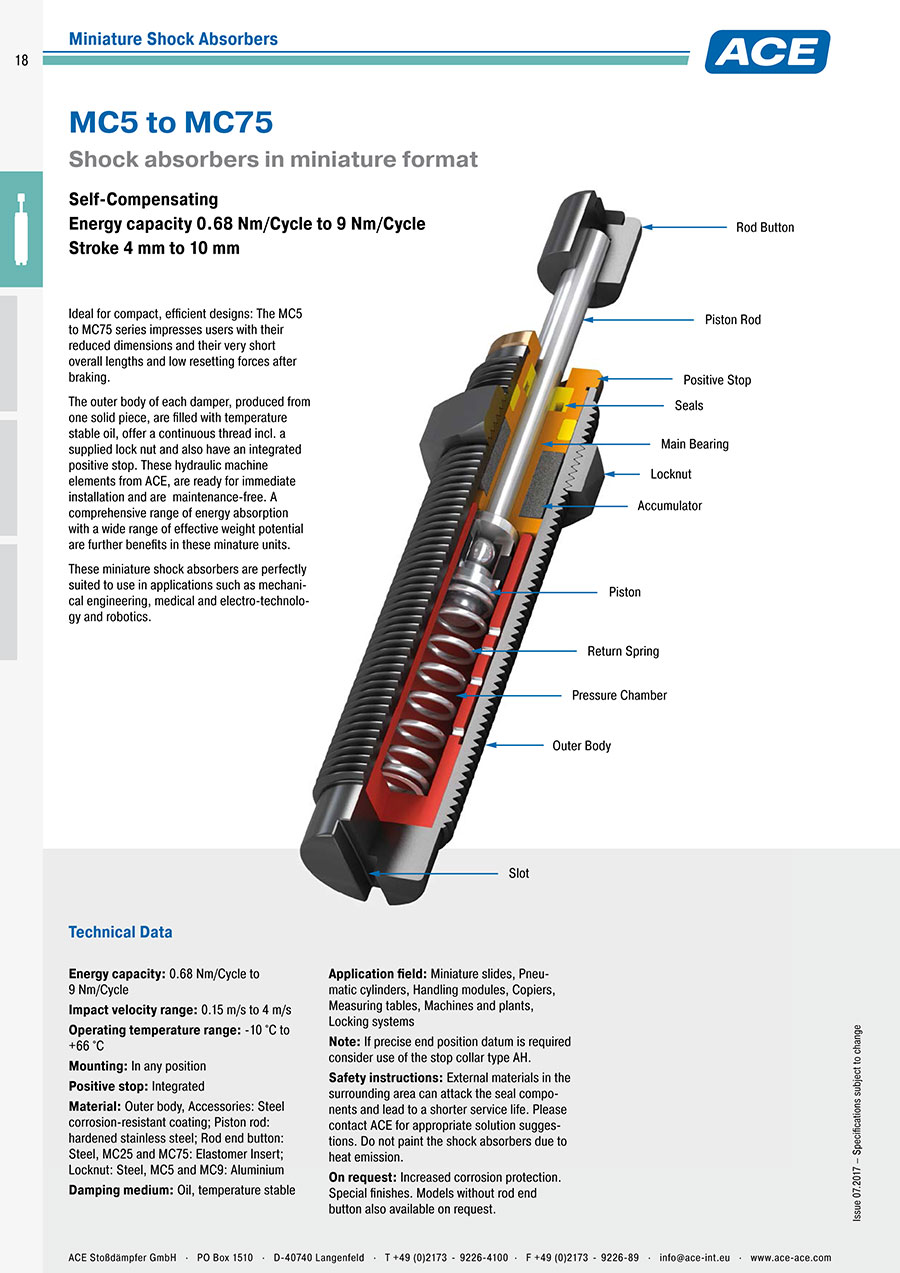

MC5 to MC75 Shock Absorbers in Miniature Format

Product Description

Self-Compensating

Energy capacity 0.68 Nm/Cycle to 9 Nm/Cycle

Stroke 4 mm to 10 mm

Ideal for compact, efficient designs: The MC5 to MC75 series impresses users with their reduced dimensions and their very short overall lengths and low resetting forces after braking.

The outer body of each damper, produced from one solid piece, are filled with temperature stable oil, offer a continuous thread incl. a supplied lock nut and also have an integrated positive stop. These hydraulic machine elements from ACE, are ready for immediate installation and are maintenance-free. A comprehensive range of energy absorption with a wide range of effective weight potential are further benefits in these minature units.

These miniature shock absorbers are perfectly suited to use in applications such as mechanical engineering, medical and electro-technology and robotics.

Energy capacity 0.68 Nm/Cycle to 9 Nm/Cycle

Stroke 4 mm to 10 mm

Ideal for compact, efficient designs: The MC5 to MC75 series impresses users with their reduced dimensions and their very short overall lengths and low resetting forces after braking.

The outer body of each damper, produced from one solid piece, are filled with temperature stable oil, offer a continuous thread incl. a supplied lock nut and also have an integrated positive stop. These hydraulic machine elements from ACE, are ready for immediate installation and are maintenance-free. A comprehensive range of energy absorption with a wide range of effective weight potential are further benefits in these minature units.

These miniature shock absorbers are perfectly suited to use in applications such as mechanical engineering, medical and electro-technology and robotics.

Technical Data

• Energy capacity: 0.68 Nm/Cycle to 9 Nm/Cycle

• Impact velocity range: 0.15 m/s to 4 m/s

• Operating temperature range: -10 °C to +66 °C

• Mounting: In any position

• Positive stop: Integrated

• Material: Outer body, Accessories: Steel corrosion-resistant coating; Piston rod: hardened stainless steel; Rod end button: Steel, MC25 and MC75: Elastomer Insert; Locknut: Steel, MC5 and MC9: Aluminium

• Damping medium: Oil, temperature stable

• Application field: Miniature slides, Pneumatic cylinders, Handling modules, Copiers, Measuring tables, Machines and plants, Locking systems

• Note: If precise end position datum is required consider use of the stop collar type AH.

• Safety instructions: External materials in the surrounding area can attack the seal components and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Do not paint the shock absorbers due to heat emission.

• On request: Increased corrosion protection. Special finishes. Models without rod end button also available on request.

• Impact velocity range: 0.15 m/s to 4 m/s

• Operating temperature range: -10 °C to +66 °C

• Mounting: In any position

• Positive stop: Integrated

• Material: Outer body, Accessories: Steel corrosion-resistant coating; Piston rod: hardened stainless steel; Rod end button: Steel, MC25 and MC75: Elastomer Insert; Locknut: Steel, MC5 and MC9: Aluminium

• Damping medium: Oil, temperature stable

• Application field: Miniature slides, Pneumatic cylinders, Handling modules, Copiers, Measuring tables, Machines and plants, Locking systems

• Note: If precise end position datum is required consider use of the stop collar type AH.

• Safety instructions: External materials in the surrounding area can attack the seal components and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Do not paint the shock absorbers due to heat emission.

• On request: Increased corrosion protection. Special finishes. Models without rod end button also available on request.

Dimensional Drawing

Performance

| Performance | |||||||||

TYPES | Max. Energy Capacity | Effective Weight | Return Force min. N | Return Force max. N | Return Time s | 1 Side Load Angle max. ° | Weight kg | ||

| W3 Nm/cycle | W4 Nm/h | me min. kg | me max. kg | ||||||

| MC5EUM-1-B | 0.68 | 2,040 | 0.5 | 4.4 | 1 | 5 | 0.2 | 2 | 0.003 |

| MC5EUM-2-B | 0.68 | 2,040 | 3.8 | 10.8 | 1 | 5 | 0.2 | 2 | 0.003 |

| MC5EUM-3-B | 0.68 | 2,040 | 9.7 | 18.7 | 1 | 5 | 0.2 | 2 | 0.003 |

| MC9EUM-1-B | 1 | 2,000 | 0.6 | 3.2 | 2 | 4 | 0.3 | 2 | 0.004 |

| MC9EUM-2-B | 1 | 2,000 | 0.8 | 4.1 | 2 | 4 | 0.3 | 2 | 0.004 |

| MC10EUML-B | 1.25 | 4,000 | 0.3 | 2.7 | 2 | 4 | 0.6 | 3 | 0.007 |

| MC10EUMH-B | 1.25 | 4,000 | 0.7 | 5 | 2 | 4 | 0.6 | 3 | 0.007 |

| MC25EUML | 2.8 | 22,600 | 0.7 | 2.2 | 3 | 6 | 0.3 | 2 | 0.020 |

| MC25EUM | 2.8 | 22,600 | 1.8 | 5.4 | 3 | 6 | 0.3 | 2 | 0.020 |

| MC25EUMH | 2.8 | 22,600 | 4.6 | 13.6 | 3 | 6 | 0.3 | 2 | 0.020 |

| MC30EUM-1 | 3.5 | 5,600 | 0.4 | 1.9 | 2 | 6 | 0.3 | 2 | 0.010 |

| MC30EUM-2 | 3.5 | 5,600 | 1.8 | 5.4 | 2 | 6 | 0.3 | 2 | 0.010 |

| MC30EUM-3 | 3.5 | 5,600 | 5 | 15 | 2 | 6 | 0.3 | 2 | 0.010 |

| MC75EUM-1 | 9 | 28,200 | 0.3 | 1.1 | 4 | 9 | 0.3 | 2 | 0.035 |

| MC75EUM-2 | 9 | 28,200 | 0.9 | 4.8 | 4 | 9 | 0.3 | 2 | 0.035 |

| MC75EUM-3 | 9 | 28,200 | 2.7 | 36.2 | 4 | 9 | 0.3 | 2 | 0.035 |

| MC75EUM-4 | 9 | 28,200 | 25 | 72 | 4 | 9 | 0.3 | 2 | 0.035 |

MC150 to MC600 Exceptionaly High Endurance And With The Lowest Resetting Force

Product Description

Self-Compensating, Rolling Diaphragm Technology

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

Tried-and-tested and durable: Due to a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptional high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes direct installation in a pressure chamber e.g. as end stop damping in pneumatic cylinders up to approx. 7 bar possible.

The rolling diaphragm also benefits the very low return forces of these maintenance-free, ready-to-install absorbers. Progressive energy capacities, with a wide range of effective weight potential make these miniature shock absorbers, complete with an integrated positive stop a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°.

Miniature shock absorbers capable of universal mounting even inside a cylinder and also available in stainless steel options. They are often used in mechanical and plant engineering, and a multitude of other applications.

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

Tried-and-tested and durable: Due to a hermetically sealed rolling diaphragm in each absorber, the MC150 to MC600 product family is suitable for an exceptional high lifetime of use with up to 25 million cycles. The rolling diaphragm technology perfected by ACE ensures complete separation of the damping fluid from the surrounding air. This makes direct installation in a pressure chamber e.g. as end stop damping in pneumatic cylinders up to approx. 7 bar possible.

The rolling diaphragm also benefits the very low return forces of these maintenance-free, ready-to-install absorbers. Progressive energy capacities, with a wide range of effective weight potential make these miniature shock absorbers, complete with an integrated positive stop a winner. Furthermore, the use of a side load adapter allows impact angles of up to 25°.

Miniature shock absorbers capable of universal mounting even inside a cylinder and also available in stainless steel options. They are often used in mechanical and plant engineering, and a multitude of other applications.

Technical Data

• Energy capacity: 20 Nm/Cycle to 136 Nm/Cycle

• Impact velocity range: 0.06 m/s to 6 m/s. Other speeds on request.

• Operating temperature range: 0 °C to 66 °C

• Mounting: in any position

• Positive stop: Integrated

• Material: Outer body, Accessories: steel corrosion-resistant coating; Main bearing: plastic; Piston rod: hardened stainless steel (1.4125, AISI 440C); Rolling diaphragm: EPDM

• Damping medium: oil, temperature stable

• Application field: linear slides, pneumatic cylinders, swivel units, handling modules, machines and plants, finishing and processing centres, measuring tables, tool machines, locking systems

• Note: If precise end position datum is required consider use of the stop collar type AH.

• Safety instructions: External materials in the surrounding area can attack the rolling seal and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Suitable for use in pressure chambers up to 7 bar.

• On request: Increased corrosion protection. Special threads or other special options.

• Impact velocity range: 0.06 m/s to 6 m/s. Other speeds on request.

• Operating temperature range: 0 °C to 66 °C

• Mounting: in any position

• Positive stop: Integrated

• Material: Outer body, Accessories: steel corrosion-resistant coating; Main bearing: plastic; Piston rod: hardened stainless steel (1.4125, AISI 440C); Rolling diaphragm: EPDM

• Damping medium: oil, temperature stable

• Application field: linear slides, pneumatic cylinders, swivel units, handling modules, machines and plants, finishing and processing centres, measuring tables, tool machines, locking systems

• Note: If precise end position datum is required consider use of the stop collar type AH.

• Safety instructions: External materials in the surrounding area can attack the rolling seal and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Suitable for use in pressure chambers up to 7 bar.

• On request: Increased corrosion protection. Special threads or other special options.

Dimensional Drawing

Performance

| Performance | |||||||||

TYPES | Max. Energy Capacity | Effective Weight | |||||||

| W3 Nm/cycle | W4 Nm/h | me min. kg | me max. kg | Return Force min. N | Return Force max. N | Return Time s | 1 Side Load Angle max. ° | Weight kg | |

| MC150EUM | 20 | 34,000 | 0.9 | 10 | 3 | 8 | 0.4 | 4 | 0.06 |

| MC150EUMH | 20 | 34,000 | 8.6 | 86 | 3 | 8 | 0.4 | 4 | 0.06 |

| MC150EUMH2 | 20 | 34,000 | 70.0 | 200 | 3 | 8 | 0.4 | 4 | 0.06 |

| MC150EUMH3 | 20 | 34,000 | 181.0 | 408 | 3 | 8 | 1.0 | 4 | 0.06 |

| MC225EUM | 41 | 45,000 | 2.3 | 25 | 4 | 9 | 0.3 | 4 | 0.13 |

| MC225EUMH | 41 | 45,000 | 23.0 | 230 | 4 | 9 | 0.3 | 4 | 0.13 |

| MC225EUMH2 | 41 | 45,000 | 180.0 | 910 | 4 | 9 | 0.3 | 4 | 0.13 |

| MC225EUMH3 | 41 | 45,000 | 816.0 | 1,814 | 4 | 9 | 0.3 | 4 | 0.13 |

| MC600EUM | 136 | 68,000 | 9.0 | 136 | 5 | 10 | 0.6 | 2 | 0.31 |

| MC600EUMH | 136 | 68,000 | 113.0 | 1,130 | 5 | 10 | 0.6 | 2 | 0.31 |

| MC600EUMH2 | 136 | 68,000 | 400.0 | 2,300 | 5 | 10 | 0.6 | 2 | 0.31 |

| MC600EUMH3 | 136 | 68,000 | 2,177.0 | 4,536 | 5 | 10 | 0.6 | 2 | 0.31 |

MC150-V4A to MC600-V4A Exceptionally High endurance With Stainless Steel Corrosion Protection

Product Description

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar.

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404).

Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in order to fulfil the authorisation conditions (NSF-H1) for this market.

Energy capacity 20 Nm/Cycle to 136 Nm/Cycle

Stroke 12 mm to 25 mm

Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar.

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404).

Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in order to fulfil the authorisation conditions (NSF-H1) for this market.

Technical Data

• Energy capacity: 20 Nm/Cycle to 136 Nm/Cycle

• Impact velocity range: 0.06 m/s to 6 m/s. Other speeds on request.

• Operating temperature range: 0 °C to 66 °C

• Mounting: In any position

• Positive stop: Integrated

• Material: Outer body, Locknut, Accessories: Stainless steel (1.4404, AISI 316L); Main bearing: Plastic; Piston rod: Hardened stainless steel (1.4125, AISI 440C); Rolling diaphragm: EPDM

• Damping medium: Oil, temperature stable

• Application field: Clean room areas, Pharmaceutical industry, Medical technology, Food industry, Linear slides, Pneumatic cylinders, Handling modules, Machines and plants, Finishing and processing centres

• Note: If precise end position datum is required consider use of the stop collar type AH.

• Safety instructions: External materials in the surrounding area can attack the rolling seal and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Suitable for use in pressure chambers up to 7 bar.

• On request: Special oil with food approval. Special threads or other special options available on request.

• Impact velocity range: 0.06 m/s to 6 m/s. Other speeds on request.

• Operating temperature range: 0 °C to 66 °C

• Mounting: In any position

• Positive stop: Integrated

• Material: Outer body, Locknut, Accessories: Stainless steel (1.4404, AISI 316L); Main bearing: Plastic; Piston rod: Hardened stainless steel (1.4125, AISI 440C); Rolling diaphragm: EPDM

• Damping medium: Oil, temperature stable

• Application field: Clean room areas, Pharmaceutical industry, Medical technology, Food industry, Linear slides, Pneumatic cylinders, Handling modules, Machines and plants, Finishing and processing centres

• Note: If precise end position datum is required consider use of the stop collar type AH.

• Safety instructions: External materials in the surrounding area can attack the rolling seal and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Suitable for use in pressure chambers up to 7 bar.

• On request: Special oil with food approval. Special threads or other special options available on request.

Dimensional Drawing

Performance

| Performance | |||||||||

TYPES | Max. Energy Capacity | Effective Weight | |||||||

| W3 Nm/cycle | W4 Nm/h | me min. kg | me max. kg | Return Force min. N | Return Force max. N | Return Time s | 1 Side Load Angle max. ° | Weight kg | |

| MC150EUM-V4A | 20 | 34,000 | 0.9 | 10 | 3 | 5 | 0.4 | 4 | 0.06 |

| MC150EUMH-V4A | 20 | 34,000 | 8.6 | 86 | 3 | 5 | 0.4 | 4 | 0.06 |

| MC150EUMH2-V4A | 20 | 34,000 | 70.0 | 200 | 3 | 5 | 0.4 | 4 | 0.06 |

| MC150EUMH3-V4A | 20 | 34,000 | 181.0 | 408 | 3 | 5 | 1.0 | 4 | 0.06 |

| MC225EUM-V4A | 41 | 45,000 | 2.3 | 25 | 4 | 6 | 0.3 | 4 | 0.13 |

| MC225EUMH-V4A | 41 | 45,000 | 23.0 | 230 | 4 | 6 | 0.3 | 4 | 0.13 |

| MC225EUMH2-V4A | 41 | 45,000 | 180.0 | 910 | 4 | 6 | 0.3 | 4 | 0.13 |

| MC225EUMH3-V4A | 41 | 45,000 | 816.0 | 1,814 | 4 | 6 | 0.3 | 4 | 0.13 |

| MC600EUM-V4A | 136 | 68,000 | 9.0 | 136 | 5 | 9 | 0.6 | 2 | 0.31 |

| MC600EUMH-V4A | 136 | 68,000 | 113.0 | 1,130 | 5 | 9 | 0.6 | 2 | 0.31 |

| MC600EUMH2-V4A | 136 | 68,000 | 400.0 | 2,300 | 5 | 9 | 0.6 | 2 | 0.31 |

| MC600EUMH3-V4A | 136 | 68,000 | 2,177.0 | 4,536 | 5 | 9 | 0.6 | 2 | 0.31 |

Información detallada

Información básica

ACE small shock absorbers: compact, maintenance-free, self-adjusting, easy to integrate, noticeably reduce the loads on devices, drives, cylinders and other applications and sustainably increase their efficiency and long service life thanks to innovative sealing technologies.

Productos similaresVer todos los productos similares

No se han encontrado productos similares para este artículo. Se ha confirmado el número de pieza