Plastic sleeves / POM / MC nylon / Bakelite / PEEK / GFK (Part Numbers - CAD Download)

(i)Remark

- Resin is a material that can be easily distorted, expanded or contracted due to temperature and humidity. Please take this into consideration when designing dimensions and storing.(Click here for material properties.)

- Please check the content on our website as the PDF does not contain the most up-to-date information.

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

- Technical Information

Back to the Category Plastic Washers/Plastic Sleeves

Technical Drawing - Plastic Washers

Available dimensions and tolerances can be found under the tab More information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Plastic Washers

| Dimension Selectable | Dimension Configurable | Material | Color | |

| CLJJ | FCLJJ | Polyacetal | White | |

| CLJK | FCLJK | Black | ||

| CLJM | FCLJM | MC Nylon | Blue | |

| CLJW | FCLJW | Standard Grade | Ivory | |

| CLJD | FCLJD | MC Nylon | CDR2 | Black |

| CLJT | FCLJT | Conductive Grade | CDR6 | |

| CLJB | FCLJB | Bakelite | Paper Base | Natural Color |

| CLJN | FCLJN | Cloth Base | Natural Color | |

| CLJF | FCLJF | Fluororesin | White | |

| CLJP | FCLJP | PEEK | Gray | |

| CLJE | FCLJE | Epoxy Glass | Green | |

Further specifications can be found under the tab More information.

Composition of a Product Code - Plastic Washers

| Part Number | - | D | - | L |

| CLJJ10 | - | 16 | - | 20.0 |

| Part Number | - | V | - | D | - | L |

| FCLJB | - | V20 | - | D30 | - | L18.5 |

Alterations - Plastic Washers

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Outer Diameter (mm) | Internal Diameter (mm) | Thickness and length | Material | Material Detail | Dimension Selecting Method | Tapping Coarse Thread Dia. Selection [VM] (mm) | Tapping Fine Thread Dia. Selection [VMA] (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | Bakelite | Bakelite (Paper Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | Bakelite | Bakelite (Paper Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | Bakelite | Bakelite (Paper Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | Bakelite | Bakelite (Paper Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 6 | 10 ~ 50 | Bakelite | Bakelite (Paper Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 8 | 10 ~ 100 | Bakelite | Bakelite (Paper Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 10 | 10 ~ 100 | Bakelite | Bakelite (Paper Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | MC Nylon | MC Nylon (EN MC501 CD R2 Equiv.) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | MC Nylon | MC Nylon (EN MC501 CD R2 Equiv.) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | MC Nylon | MC Nylon (EN MC501 CD R2 Equiv.) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | MC Nylon | MC Nylon (EN MC501 CD R2 Equiv.) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 6 | 10 ~ 50 | MC Nylon | MC Nylon (EN MC501 CD R2 Equiv.) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 8 | 10 ~ 100 | MC Nylon | MC Nylon (EN MC501 CD R2 Equiv.) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 10 | 10 ~ 100 | MC Nylon | MC Nylon (EN MC501 CD R2 Equiv.) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | Epoxy Glass | Epoxy Glass | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | Epoxy Glass | Epoxy Glass | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | Epoxy Glass | Epoxy Glass | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | Epoxy Glass | Epoxy Glass | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 6 | 10 ~ 50 | Epoxy Glass | Epoxy Glass | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 8 | 10 ~ 100 | Epoxy Glass | Epoxy Glass | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 10 | 10 ~ 100 | Epoxy Glass | Epoxy Glass | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | Fluororesin | Fluororesin | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | Fluororesin | Fluororesin | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | Fluororesin | Fluororesin | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | Fluororesin | Fluororesin | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 6 | 10 ~ 50 | Fluororesin | Fluororesin | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 8 | 10 ~ 100 | Fluororesin | Fluororesin | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 10 | 10 ~ 100 | Fluororesin | Fluororesin | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 6 | 10 ~ 50 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 8 | 10 ~ 100 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 10 | 10 ~ 100 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 6 | 10 ~ 50 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 8 | 10 ~ 100 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 10 | 10 ~ 100 | Polyacetal | Polyacetal | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | MC Nylon | MC Nylon | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | MC Nylon | MC Nylon | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | MC Nylon | MC Nylon | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | MC Nylon | MC Nylon | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 6 | 10 ~ 50 | MC Nylon | MC Nylon | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 8 | 10 ~ 100 | MC Nylon | MC Nylon | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 10 | 10 ~ 100 | MC Nylon | MC Nylon | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | Bakelite | Bakelite (Fabric Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | Bakelite | Bakelite (Fabric Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | Bakelite | Bakelite (Fabric Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | Bakelite | Bakelite (Fabric Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 6 | 10 ~ 50 | Bakelite | Bakelite (Fabric Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 8 | 10 ~ 100 | Bakelite | Bakelite (Fabric Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 10 | 10 ~ 100 | Bakelite | Bakelite (Fabric Type) | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 2 | 10 ~ 30 | PEEK | PEEK | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 3 | 10 ~ 30 | PEEK | PEEK | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 4 | 10 ~ 50 | PEEK | PEEK | Dimension Selectable | - | - | ||

- | 1 | 6 Days | 10 | 12 | 5 | 10 ~ 50 | PEEK | PEEK | Dimension Selectable | - | - |

Loading...

Back to the Category Plastic Washers/Plastic Sleeves

Technical Drawing - Plastic Washers

Specification Tables - Plastic Washers

| Part Number | D | L | Unit Price | ||||||||||||||||||||||||||||

| Type | V | Selection | 0.5mm Increment | CLJJ CLJK | CLJM CLJW | CLJD | CLJB | CLJN | CLJT | CLJF | CLJP | CLJE | |||||||||||||||||||

| CLJJ CLJK CLJM CLJW CLJD CLJT CLJB CLJN CLJF CLJP CLJE | 2 | (4) | 5 | 6 | 8 | 10 | 11 | 12 | (4)V2 only | 10.0 | ~ | 25.0 | |||||||||||||||||||

| 3 | 25.5 | ~ | 30.0 | ||||||||||||||||||||||||||||

| 4 | (6) | 8 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 20 | (6)V4 only | 10.0 | ~ | 25.0 | |||||||||||||||||

| 5 | 25.5 | ~ | 50.0 | ||||||||||||||||||||||||||||

| 6 | 8 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 20 | 25 | 10.0 | ~ | 25.0 | ||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 8 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 20 | 25 | 30 | 10.0 | ~ | 25.0 | ||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 10 | 12 | 13 | 14 | 15 | 16 | 20 | 25 | 30 | 10.0 | ~ | 25.0 | ||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 35 | 40 | 50 | 10.0 | ~ | 25.0 | ||||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 12 | 15 | 16 | 20 | 25 | 30 | 10.0 | ~ | 25.0 | |||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 35 | 40 | 50 | 10.0 | ~ | 25.0 | ||||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 20 | 25 | 30 | 10.0 | ~ | 25.0 | ||||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 15 | 35 | 40 | 50 | 10.0 | ~ | 25.0 | |||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 16 | 75.5 | ~ | 100.0 | ||||||||||||||||||||||||||||

| 60 | 10.0 | ~ | 25.0 | - | - | - | - | ||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| (25) | 30 | (25)V20 only | 10.0 | ~ | 25.0 | ||||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 20 | 35 | 40 | 50 | 10.0 | ~ | 25.0 | |||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 25 | 75.5 | ~ | 100.0 | ||||||||||||||||||||||||||||

| 60 | 10.0 | ~ | 25.0 | - | - | - | - | ||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 30 | 40 | 50 | 10.0 | ~ | 25.0 | ||||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| 60 | 10.0 | ~ | 25.0 | - | - | - | - | ||||||||||||||||||||||||

| 25.5 | ~ | 50.0 | |||||||||||||||||||||||||||||

| 50.5 | ~ | 75.0 | |||||||||||||||||||||||||||||

| 75.5 | ~ | 100.0 | |||||||||||||||||||||||||||||

| Part Number | V | D | L | Unit Price | ||||||||

| V2.6 or Less Selection | D4 ~ 20: 0.5mm Increment | 0.5mm Increment | FCLJJ FCLJK | FCLJM FCLJW | FCLJD | FCLJB | FCLJN | FCLJT | FCLJF | FCLJP | FCLJE | |

| V3.0 or More: 0.5mm Increment | D21 or More: 1mm Increment | |||||||||||

| FCLJJ FCLJK FCLJM FCLJW FCLJD FCLJT FCLJB FCLJN FCLJF FCLJP FCLJE | 4.0~10 | 10.0~ 25.0 | ||||||||||

| (0.5mm Increment) | 25.5~ 50.0 | |||||||||||

| D≤5L≤50 | 50.5~ 75.0 | |||||||||||

| 0 | 75.5~100.0 | |||||||||||

| (No Hole Machining) | 10.5~20 (0.5mm Increment) | 10.0~ 25.0 | ||||||||||

| 25.5~ 50.0 | ||||||||||||

| 50.5~ 75.0 | ||||||||||||

| 2.0 | 75.5~100.0 | |||||||||||

| 21~30 (1mm Increment) | 10.0~ 25.0 | |||||||||||

| 2.6 | 25.5~ 50.0 | |||||||||||

| 50.5~ 75.0 | ||||||||||||

| 75.5~100.0 | ||||||||||||

| 3.0~55.0 | 31~40 (1mm Increment) | 10.0~ 25.0 | ||||||||||

| (0.5mm Increment) | 25.5~ 50.0 | |||||||||||

| 50.5~ 75.0 | ||||||||||||

| L≤ 50.0 | 75.5~100.0 | |||||||||||

| V≤D-2 | 41~50 (1mm Increment) | 10.0~ 25.0 | ||||||||||

| 25.5~ 50.0 | ||||||||||||

| L≥ 50.5 | 50.5~ 75.0 | |||||||||||

| V≤D-6 | 75.5~100.0 | |||||||||||

| 51~60 (1mm Increment) | 10.0~ 25.0 | - | - | - | - | |||||||

| 25.5~ 50.0 | ||||||||||||

| 50.5~ 75.0 | ||||||||||||

| 75.5~100.0 | ||||||||||||

| 61~80 (1mm Increment) | 10.0~ 25.0 | - | - | - | - | |||||||

| 0 | 25.5~ 50.0 | |||||||||||

| (No Hole Machining) | 50.5~ 75.0 | |||||||||||

| 75.5~100.0 | ||||||||||||

| 3.0~90.0 | 81~100 (1mm Increment) | 10.0~ 25.0 | - | - | - | - | ||||||

| (0.5mm Increment) | 25.5~ 50.0 | |||||||||||

| V≤D-6 | 50.5~ 75.0 | |||||||||||

| 75.5~100.0 | ||||||||||||

| Machining Conditions | L ≤Vx8 | No specification available for those without value. | ||||||||||

Alterations - Plastic Washers

General Information - Plastic Washers

Selection details of plastic washers/plastic sleeves

- Material: MC-nylon, polyacetal (POM), Bakelit, epoxy glass, polyether ether ketone (PEEK), fluoroplastic, polyslider, ceramic, polycarbonate (PC), polyamide (PA), polytetrafluoroethylene (PTFE), Duracon, Duranex, ABS, glass (lime-sodium glass)

- Outer diameter: 2 to 100 mm

- Inner diameter: 1 to 90 mm

- Thickness, length: 0.1 to 500 mm

- Forms: cylindrical, with collar, with pins, with countersunk bore, with guide, square washers

Description/Basics of plastic washers/plastic sleeves

Sleeves in general, are among the most commonly used machine elements to create a distance between two components. Plastic sleeves and ceramic sleeves offer added value compared to conventional metal collars.

Plastic sleeves and plastic sleeves with a collar have some advantages over their metallic counterparts. In addition to creating and maintaining a distance, they also have an insulating effect. The insulation effect refers to thermal insulation or electrical insulation depending on the material. In addition, their similarity to natural materials is greater than with metal sleeves. As a result, plastic washers and plastic sleeves (depending on the material) expand to the same extent under the influence of heat, such as wood or similar soft materials.

Plastic washers, as well as washers, enable an increase in surface compression. However, their resistance to pressure loads is lower depending on the material selected than that of a similarly large metal washer. For this purpose, the advantage of thermal and electrical insulation effects exists in plastic washers.

MISUMI also offers plastic washers and plastic sleeves with gliding properties. For example, washers and sleeves made of fluoroplastics are suitable for reducing friction resistances in hinge constructions. It should be noted that plastic sleeves do not replace plain bearings.

Polyether ether ketone (PEEK) has excellent thermal insulating properties. Depending on the strength and material composition, PEEK has a melting point of up to 300°C. It is therefore suitable, among other things, for insulating heating and cooling lines, for example. Due to the quality of the surface, the material has particularly good adhesive properties.

Polyacetal, also called POM, is characterized by its very good machinability and excellent mechanical properties. Polyacetal (POM) products are widely used in various branches of mechanical engineering.

At MISUMI you will find washers and sleeves made of various variants of MC Nylon. In addition to the standard version, a conductive and antistatic type is also offered. Thus, MC Nylon can be used in a wide variety of applications.

The different versions and shapes of the plastic washers and plastic sleeves allow utilising them in a wide variety of applications. Thus, plastic washers can be used, for example, as bearing mountings up to the assembly of printed circuit boards.

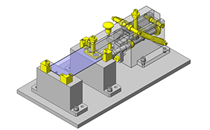

Application Examples

Plastic sleeve as thermally insulating spacer sleeve

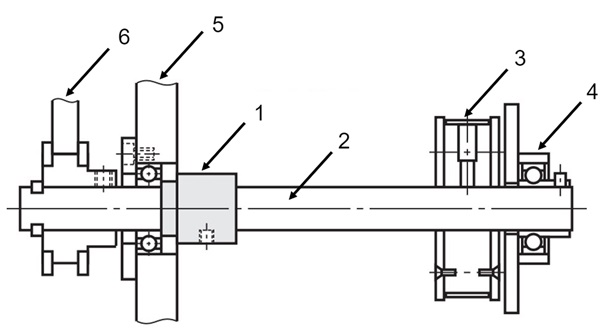

(1) Plastic sleeves, (2) Cylindrical plastic sleeve, (3) Plastic washer, (4) Hexagon socket screws, (5) Washer, (6) Hexagon nut

Plastic sleeve as bearing ring

(1) Plastic sleeve with guide, (2) Rotary shaft, (3) Timing pulley, (4) Ball bearing (5) Bearing with housing, (6) Drive wheel

Basic information

| Shape | Standard | Hole Type | Through Hole | Sale Type | Sold Separately |

|---|

Configure

Basic Attributes

-

Internal Diameter(mm)

-

Thickness and length

-

Material

- MC Nylon

- Polyacetal

- Bakelite

- Epoxy Glass

- PEEK

- Fluororesin

-

Material Detail

-

Dimension Selecting Method

- Dimension Configurable Type

- Dimension Selectable

-

Tapping Coarse Thread Dia. Selection [VM](mm)

-

Tapping Fine Thread Dia. Selection [VMA](mm)

-

Type

- CLJB

- CLJD

- CLJE

- CLJF

- CLJJ

- CLJK

- CLJM

- CLJN

- CLJP

- CLJT

- CLJW

- FCLJB

- FCLJD

- FCLJE

- FCLJF

- FCLJJ

- FCLJK

- FCLJM

- FCLJN

- FCLJP

- FCLJT

- FCLJW

-

Outer Diameter(mm)

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 6 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

Do ceramic washers have the same strength as ceramic sleeves?

-

Answer:

Due to a radial lamination of the ceramic material, ceramic sleeves have a lower compressive strength than ceramic washers (vertically laminated). Detailed information and comparison values can be found here.

-

Question:

What is the thermal expansion of plastic sleeves and plastic washers?

-

Answer:

Plastic sleeves and plastic washers react sensitively to fluctuations in ambient temperature. The length of synthetic resin sleeves varies depending in a ratio of up to 1°C = 0.1 mm depending on the temperature . Details on the thermal expansion of other materials available at MISUMI can be found in this PDF.

-

Question:

Do you have washers made of a material that provide electric insulation?

-

Answer:

Most plastics have an electrically insulating effect. The level of insulation differs depending on the material. Polycarbonate has a very good electrically insulating effect. In addition to its good electrical insulating effect, it is also superior to most conventional plastics in terms of mechanical aspects.

-

Question:

Which material is suitable for both low and high temperatures?

-

Answer:

Polyether ether ketone (PEEK) and polytetrafluoroethylene (PTFE) have an operating temperature of approx. -50°C (PEEK), respectively -40°C (PTFE) and up to +250°C.

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry