Rubber-metal elements / cylindrical, stepped / external thread on both sides / eyelet plate, stainless steel / CR, NBR conductive / A60 (Part Numbers - CAD Download)

- Volume Discount

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

Back to the Category Antivibration Materials

Technical Drawing - Rubber-Metal Elements

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Rubber-Metal Elements

| Type | Material | Hardness | Accessory | |

| Main Body | Metal Fitting | |||

| DBGOMA | Conductive Nitrile Rubber | EN 1.4301 Equiv. | Shore A60 | Nut, Spring Washer 2 pcs. each |

| EBGOMA | Chloroprene Rubber | |||

■Threaded Stud, Plate Mount

| Type | Material | Hardness | Accessory | |

| Main Body | Metal Fitting | |||

| DBGOMP | Conductive Nitrile Rubber | EN 1.4301 Equiv. | Shore A60 | Nut, Spring Washer 1 pc. each |

| EBGOMP | Chloroprene Rubber | |||

Further specifications can be found under the tab More information.

Composition of a Product Code - Rubber-Metal Elements

| Part Number |

| DBGOMA15150 |

General Information - Rubber-Metal Elements

Oscillation Damper/Stop Buffer/Vibration Damper Selection Details

- Material: natural rubber (NR), chloroprene rubber (CR), nitrile rubber (NBR), silicone (SI)

- Mounting plate: steel, stainless steel

- Hardness: Shore A45, A60, C19.7, C25.3, C29.8, C30, C38.0, C44, C44.3, C44.5, C50, C52.5

- Properties: weather resistant, water resistant, oil resistant, ozone resistant, electrically conductive

- Height: 3 to 34 mm

- Thread: M4 to M8

- Load: 1.77 N to 1225 N

Description/Basics

Rubber metal elements, or also called rubber metal buffers, are generally used for oscillation and vibration damping. They are not only used to reduce structure-borne noise (transmitting vibrations), but also demonstrably reduce noise generation. This property plays an increasingly important role in the industry and mechanical engineering, as noise reduction plays an increasingly important role.

The vulcanized rubber buffers are generally fitted with mounting plates on one side or both sides. The mounting plates are provided with internal threads, external threads or through holes. Depending on the installation requirements, MISUMI offers the appropriate vibration damper.

MISUMI offers vibration-damping rubber in various materials, with different advantages and properties. Not only the respective loads and vibration frequencies must be observed when selecting rubber buffers, but depending on the application the resistance to environmental influences (e.g., oil resistance) also plays an important role. The design of the damping material also influences the damper characteristic, which can develop a degressive or progressive damping effect. It should be noted that vibration dampers do not allow complete isolation and decoupling of vibrations, but this is greatly reduced. You can find further details under the tab More information.

An overview of the different vibration dampers and materials can be found in the selection process as a PDF .

Rubber metal elements are often used to reduce vibration and noise in a wide variety of applications in almost all industries. Motors, pumps, and other vibration generating units are often elastically supported with vibration dampers.

Natural Rubber (NR)

Rubber metal elements made of natural rubber offer the advantage that they form a low heat development (low "heat-build-up" values) during internal creep. However, a vibrating damper made of natural rubber should not come into contact with oil, as this will cause the rubber buffer to swell and become porous, which can reduce its damping properties.

Chloroprene Rubber (CR)

Vibration dampers made of chloroprene rubber have an excellent weather resistance and good oil and ozone resistance. However, rubber buffers made of chloroprene rubber have only limited resistance to water.

Nitrile Rubber (NBR)

Rubber buffers made of nitrile rubber have the advantage of high tear resistance and abrasion resistance. In addition, rubber buffers made of nitrile rubber have good resistance to hydrocarbons, fats and oils. As a result, this material is often used for seals because it also has good temperature resistance. Furthermore, vibration dampers made of nitrile rubber are electrically conductive.

Silicone and Silicone Gel (SI)

Rubber, silicone metal bearings are very temperature-resistant, water-resistant and durable in response to the other materials. Vibration dampers made of silicone rubber also have very good chemical resistance. Silicone is a soft material that has very good damping properties, but can absorb only a small amount of supporting force.

Further information on the hardness of the various rubbers can be found under Rubber Properties as a PDF.

Application Examples - Rubber-Metal Elements

![Application example - rubber metal buffer with [Aug] plate and internal threads - vibration dampers on base plates](https://de.misumi-ec.com/linked/item/10300280030/img/Anwendungbeispiel_-_Gummi_Metall_Puffer_mit_Augplatte_und_Innengewinde.jpg)

Application example: vibration damper internal thread and eye plate

(1) Screw , (2) mounting plate , (3) screw

![Application example - rubber metal buffer with [Aug] plate and external thread - vibration damper on base plates](https://de.misumi-ec.com/linked/item/10300280030/img/Anwendungsbeispiel_-_Gummi_Metall_Puffer_mit_Augplatte_und_Innengewinde.jpg)

Application example: vibration damper external thread and eye plate

(1) Nut , (2) mounting plate , (3) screw

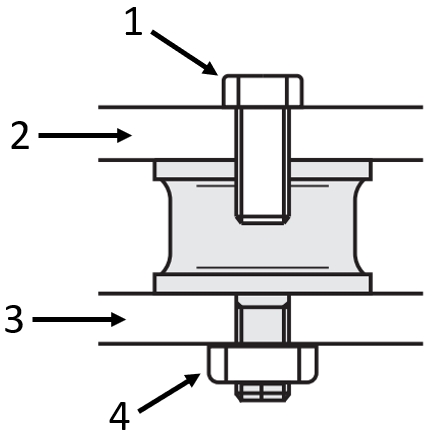

Application example: threaded vibration absorber

(1) Screw , (2) mounting plate , (3) base plate (meviy), (4) nut

Application example: vibration absorber with external thread

(1) Nut , (2) mounting plate , (3) base plate (meviy)

Industrial Applications

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| DBGOMP20150 |

| DBGOMP20200 |

| DBGOMP25180 |

| DBGOMP30180 |

| DBGOMP40250 |

| EBGOMP20150 |

| EBGOMP20200 |

| EBGOMP25180 |

| EBGOMP30180 |

| EBGOMP40250 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Maximum Operating Load (N) | Properties | Connection Type | Connecting Screw M | Height H (mm) | Spring Constant (N/mm) | Material | Operating Temperature Range (°C) | Applied Load (N) | O.D. D (Ø) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

10.59 € | 1 | Available | 5 Days | - | 191 | Electrical Conductivity | Threadeds, Plate Stopper Type | 6 | 15 | 130 | [Nitrile Rubber] Conductive Nitrile Rubber | - | 98~191 | 20 | |

10.83 € | 1 | Available | 5 Days | - | 98 | Electrical Conductivity | Threadeds, Plate Stopper Type | 6 | 20 | 78 | [Nitrile Rubber] Conductive Nitrile Rubber | - | 59~98 | 20 | |

12.46 € | 1 | Available |

Same day

Stock | - | 250 | Electrical Conductivity | Threadeds, Plate Stopper Type | 6 | 18 | 200 | [Nitrile Rubber] Conductive Nitrile Rubber | - | 112~250 | 25 | |

14.48 € | 1 | Available | 5 Days | - | 450 | Electrical Conductivity | Threadeds, Plate Stopper Type | 8 | 18 | 310 | [Nitrile Rubber] Conductive Nitrile Rubber | - | 226~450 | 30 | |

18.63 € | 1 | Available | 5 Days | - | 930 | Electrical Conductivity | Threadeds, Plate Stopper Type | 8 | 25 | 340 | [Nitrile Rubber] Conductive Nitrile Rubber | - | 196~930 | 40 | |

10.07 € | 1 | Available | 5 Days | 10 | 191 | Durability / Weather Resistance / Water Resistance / Oil Resistance / Ozone Resistance | Threadeds, Plate Stopper Type | 6 | 15 | 130 | [Chloroprene] Chloroprene Rubber | -20~70 | 98~191 | 20 | |

10.33 € | 1 | Available | 5 Days | 10 | 98 | Durability / Weather Resistance / Water Resistance / Oil Resistance / Ozone Resistance | Threadeds, Plate Stopper Type | 6 | 20 | 78 | [Chloroprene] Chloroprene Rubber | -20~70 | 59~98 | 20 | |

11.97 € | 1 | Available | 5 Days | 10 | 250 | Durability / Weather Resistance / Water Resistance / Oil Resistance / Ozone Resistance | Threadeds, Plate Stopper Type | 6 | 18 | 200 | [Chloroprene] Chloroprene Rubber | -20~70 | 112~250 | 25 | |

13.60 € | 1 | Available | 5 Days | 10 | 450 | Durability / Weather Resistance / Water Resistance / Oil Resistance / Ozone Resistance | Threadeds, Plate Stopper Type | 8 | 18 | 310 | [Chloroprene] Chloroprene Rubber | -20~70 | 226~450 | 30 | |

17.51 € | 1 | Available | 5 Days | 10 | 930 | Durability / Weather Resistance / Water Resistance / Oil Resistance / Ozone Resistance | Threadeds, Plate Stopper Type | 8 | 25 | 340 | [Chloroprene] Chloroprene Rubber | -20~70 | 196~930 | 40 |

Loading...

Back to the Category Antivibration Materials

Technical Drawing - Rubber-Metal Elements

Open the technical drawing in the new window

Specification Tables - Rubber-Metal Elements

| Part Number | D1 | D2 | H1 | H2 | t | ℓ | S | M (Coarse Thread) | W1xW2 | h | P | Allowable Load N {kgf} | Working Load N {kgf} | Spring Constant N/mm {kgf/cm} | X Direction Allowable Load N {kgf} | Rigidity Ratio kx/kz | |

| Type | No. | ||||||||||||||||

| Both Ends Threaded Studs DBGOMA EBGOMA Threaded Stud, Plate Mount DBGOMP EBGOMP | 12160 | 12 | 10 | 16 | 12.0 | 2.0 | 13 | 11 | 5 | - | - | - | 110 {11} | 30~78 {3~8} | 41 {42} | 25 {2.5} | 0.2 |

| 15150 | 15 | 12 | 15 | 11.0 | 16 | 12 | 160 {16} | 59~130 {6~13} | 74 {75} | 34 {3.4} | 0.2 | ||||||

| 20150 | 20 | 15 | 13 | 6 | 49x20 | 6.5x8.5 Slotted Hole | 36 | 280 {29} | 98~191 {10~19} | 130 {130} | 69 {7} | 0.15 | |||||

| 20200 | 20 | 16.0 | 180 {18} | 59~98 {6~10} | 78 {80} | 49 {5} | 0.19 | ||||||||||

| 25180 | 25 | 20 | 18 | 13.4 | 2.3 | 20 | 16 | 56x25 | 42 | 490 {50} | 112~250 {11~25} | 200 {200} | 98 {10} | 0.16 | |||

| 30180 | 30 | 25 | 18 | 13.4 | 23 | 20 | 8 | 62x30 | 48 | 890 {91} | 226~450 {23~46} | 310 {310} | 170 {17} | 0.16 | |||

| 40250 | 40 | 34 | 25 | 20.4 | 33 | 25 | 76x40 | 9x11 Slotted Hole | 60 | 1810 {185} | 196~930 {20~95} | 340 {340} | 360 {37} | 0.17 | |||

| Item | Unit | Value |

| Specific Gravity | - | 1.31 |

| Hardness | Shore A | 60 |

| Elongation | % | 545 |

| Tensile Strength | MPa | 11.8 |

| Specific Volume Resistivity | Ω • cm | 8x103 |

The above values are not guaranteed values but an example of measured values.

More Information - Rubber-Metal Elements

[DBGOMA, DBGOMP, DBGONA, DBGONP]

· The problem of antivibration rubber, susceptibility to insulation has been solved by the high electroconductive rubber with volume resistivity value of 103Ω · cm.

[EBGOMA, EBGOMP, EBGONA, EBGONP]

· High quality product made of chloroprene rubber excellent in durability

[Common]

· Mounting studs are made of EN 1.4301 Equiv. The tips are slotted and the mounting holes on flanges are also slotted for ease of mounting.

Basic information

| Type | Antivibration Rubbers | Application | Vibration Control | Hardness(Shore A) | 60 |

|---|---|---|---|---|---|

| Antivibration Rubber Type | Round Type | Body Color | Black |

Configure

Stock

-

- Show only stock items

Basic Attributes

-

Maximum Operating Load(N)

-

Properties

- Durability

- Weather Resistance

- Water Resistance

- Oil Resistance

- Ozone Resistance

- Electrical Conductivity

-

Connecting Screw M

- 5

- 6

- 8

-

Height H(mm)

-

Spring Constant(N/mm)

-

Material

- Chloroprene

- Nitrile Rubber

- Chloroprene

-

O.D. D(Ø)

- 12

- 15

- 20

- 25

- 30

- 40

-

Type

- DBGOMA

- DBGOMP

- EBGOMA

- EBGOMP

-

Connection Type

- Both Ends Threaded Studs

- Threadeds, Plate Stopper Type

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- Same day

- 5 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

Can the rubber buffers be subjected to tension?

-

Answer:

Rubber buffer or rubber metal elements should not be subjected to pull. In this case, the vulcanized holding plate may be separated from the damping material. Therefore, vibration dampers should only be used in designs that subject it to pressure. This ensures that the vibration damper does not suffer a fatigue fracture.

-

Question:

Do you have oil-resistant rubber buffers?

-

Answer:

In an environment with oil-containing substances, a rubber metal buffer made of nitrile rubber (NBR) can be used. Since this material is oil-resistant, it is quite often used for seals. Other materials can swell up in contact with greases or oils, which will cause the rubber buffer to fail and cause it to lose its damping properties.

-

Question:

Which rubber buffer can be used in water vapour?

-

Answer:

A rubber metal buffer made of silicone rubber or silicone gel can be used here. It is highly resistant to water and offers very good damping properties. Similar to sanitary systems, this material is very resistant to aging, chemicals and temperature.

-

Question:

What is the permissible operating temperature of rubber metal silicone buffers?

-

Answer:

The maximum temperature resistance of silicone rubber buffers is at approx. 200°C. It is recommended to check the temperature resistance of the respective product. This can be found under the More Information tab.

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry