Stopper bolts / screw version / T standard (STEHN5.5A)

- Volume Discount

Product Details:

Manufacturer part number: STEHN5.5A

Brand: MISUMI

Price: 5.19 €

Delivery time: Same day

Technical Data:

Tip O.D.: 5.5 mm

Material: [Steel] EN 1.7220 Equiv.

Hardness: 46 - 50HRC

Surface Treatment: Electroless Nickel Plating

T Dimension Specifying Method: T Fixed Type

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

STEHN5.5A

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

Back to the Category Stopper Bolts

Technical Drawing - Stopper Bolts

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More Information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Stopper Bolts

| T | Type | Material | Hardness | Surface Treatment |

| Fixed | STEHN | EN 1.7220 Equiv. | 46~50HRC | Electroless Nickel Plating |

| SSTEH | EN 1.4037 Equiv. | 50~55HRC | - | |

| Configurable | STFHN | EN 1.7220 Equiv. | 32~38HRC | Electroless Nickel Plating |

| SSTFH | EN 1.4037 Equiv. | 40~45HRC | - |

Further specifications can be found under the tab More Information.

Composition of a Product Code - Stopper Bolts

| Part Number | - | H | |

| (T Fixed) (T Configurable) | STEHN5.5A STFHN10 | - | 6.5 |

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| STEHN5.5A |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Tip O.D. (mm) | Material | Hardness | Surface Treatment | T Dimension Specifying Method | Head Height T (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

5.19 € | 1 | Available |

Same day

Stock | 10 | 5.5 | [Steel] EN 1.7220 Equiv. | 46 - 50HRC | Electroless Nickel Plating | T Fixed Type | 3 |

Loading...

Back to the Category Stopper Bolts

Technical Drawing - Stopper Bolts

Open the technical drawing in the new window

Specification Tables - Stopper Bolts

| Part Number | T | M (Coarse) | L | (C) | Unit Price | ||

| Type | B | STEHN | SSTEHN | ||||

| (EN 1.7220 Equiv.) STEHN (EN 1.4037 Equiv.) SSTEH | 5.5A | 3 | 3 | 5 | 6.4 | ||

| 5.5 | 5 | 3 | 5 | 6.4 | |||

| 7 | 5 | 4 | 5 | 8.1 | |||

| 8 | 5 | 5 | 6 | 9.2 | |||

| 10 | 5 | 6 | 6 | 11.5 | |||

| 10B | 8 | 6 | 9 | 11.5 | |||

| 13 | 5 | 8 | 10 | 15 | |||

| 13A | 8 | 8 | 10 | 15 | |||

| 13B | 8 | 8 | 12 | 15 | |||

| 14 | 5 | 8 | 10 | 16.2 | |||

| 14A | 8 | 8 | 10 | 16.2 | |||

| 14B | 8 | 8 | 12 | 16.2 | |||

| 17 | 5 | 10 | 12 | 19.6 | |||

| 17A | 8 | 10 | 12 | 19.6 | |||

| 17B | 8 | 10 | 15 | 19.6 | |||

| 19 | 5 | 12 | 15 | 21.9 | |||

| 19A | 8 | 12 | 15 | 21.9 | |||

| 19B | 8 | 12 | 18 | 21.9 | |||

■T Configurable Type

| Part Number | T Configurable 0.5mm Increment | M (Coarse) | L | (C) | Unit Price | ||

| Type | B | STFHN | SSTFH | ||||

| (EN 1.7220 Equiv.) STFHN (EN 1.4037 Equiv.) SSTFH | 5.5 | 2.0~10.0 | 3 | 5 | 6.4 | ||

| 7 | 2.0~10.0 | 4 | 5 | 8.1 | |||

| 8 | 2.0~10.0 | 5 | 6 | 9.2 | |||

| 10 | 5.0~30.0 | 6 | 6 | 11.5 | |||

| 13 | 5.0~30.0 | 8 | 10 | 15 | |||

| 14 | 5.0~30.0 | 8 | 10 | 16.2 | |||

| 17 | 10.0~50.0 | 10 | 12 | 19.6 | |||

| 19 | 10.0~50.0 | 12 | 15 | 21.9 | |||

General Information - Stopper Bolts

Stop bolt selection details

- Material: steel, stainless steel

- Coatings: uncoated, nickel-plated

- Hardness: 32 to 55HRC

- Wrench width: 3 to 20 mm

- Head height: up to 50 mm

- Threads: M3 to M12

- Head diameter: 5 to 20 mm

- Diameter mounting side: 2 to 12 mm (m6)

- Brush head: polyurethane rubber (PUR) with Shore A90

Description/Basics

The stopper bolt from the group of stopper elements serves primarily as a stop in mechanical engineering (collision protection). In addition, it is increasingly used to determine the final position for workpieces and in movable applications in device construction (e.g., workpiece carriers).

In principle, MISUMI offers two mounting variants of the stop bolts. The commercially available variants are threaded stop bolts. Threaded stopper bolts have the advantage that they are easy to assemble and disassemble. Furthermore, the thread of the stop bolt can be used to adjust the spacing and the end position.

In addition, MISUMI offers non-threaded stop bolts for pressing in with fit tolerance as a further assembly variant. These stop bolts can also be inserted into the component to be moved in the event of frequent collisions to protect the component. In order to strengthen the component protection, the different designs of the stop bolts can also be combined with one another.

The undercuts at the transition from the shaft to the head ensures that in the event of impact energy can be transferred to the support surface over as large an area as possible.

As a rule, stop bolts have a flat contact surface. Correct alignment is necessary so that the entire contact surface can be used. If exact alignment is not possible, MISUMI also offers stop bolts with a spherical contact surface.

Both variants of stop bolts are protected from increased wear or damage with a hardened (tempered) contact surface. A low-wear stop bolt is necessary, especially with high cycles and frequent collisions. The stop bolts are also available with a cushioned contact surface made of polyurethane rubber. These can reduce the shock impulse, vibrations and associated noise.

If there is only a limited installation space, MISUMI offers the special form with a key hole on the head side. This facilitates the adjustment and installation of the stop bolt even when access is difficult.

Threaded stopper blocks are suitable for fastening stop bolts that have a configurable height.

Alternatively, MISUMI offers a large number of stopper bolts with brush heads and dampers, which, contrary to the stop bolt, have primarily damping properties.

If component guidance is required in addition to rigid and precise positioning, a height adjusting pin with a collar can serve as a guided stopper.

Application examples

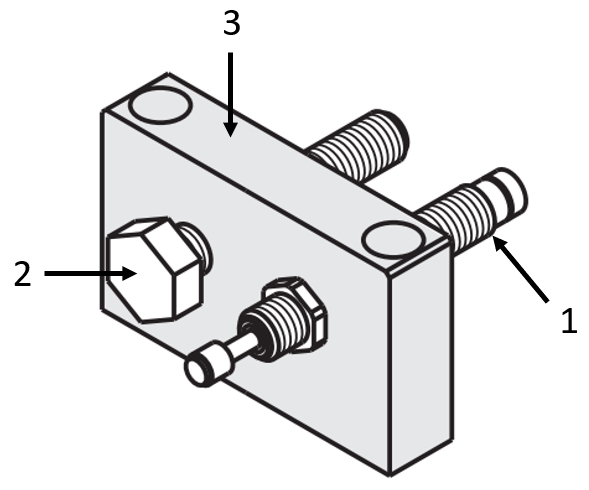

Application example – end stop with threaded stop bolt

(1) Adjustable shock absorber, (2) Stop bolts, (3) Threaded Stopper Block

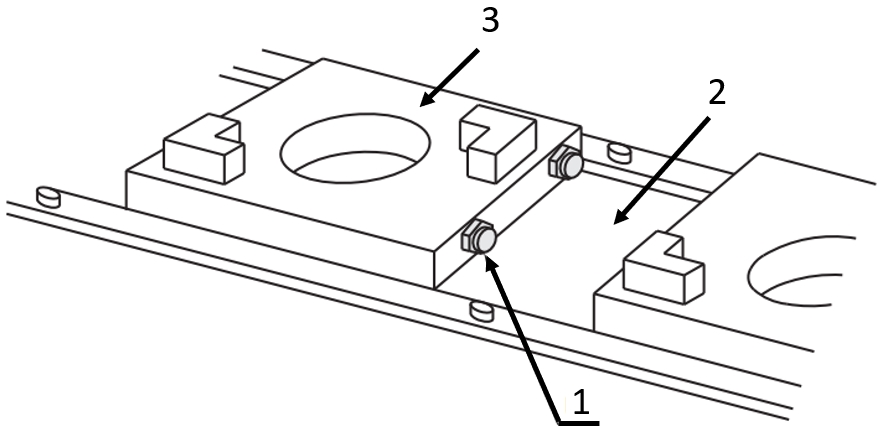

Application example – workpiece carrier with stop bolt

(1) Stop bolt with rubber, (2) ฺBelt conveyor, (3) Workpiece carrier

Industrial Applications

Basic information

| Mounting Method | Threads | Tip Shape | Flat |

|---|

This page is Stopper bolts / screw version / T standard, part number STEHN5.5A.

You can find the detail information about specifications and dimensions on part number STEHN5.5A.

Configure

Stock

-

- Show only stock items

Basic Attributes

-

Type

- SSTEH

- SSTFH

- STEHN

- STFHN

-

Tip O.D.(mm)

-

Material

- Steel

- Stainless Steel

- Steel

-

Hardness

- 32-38HRC

- 40 - 45HRC

- 46 - 50HRC

- 50 - 55HRC

-

Surface Treatment

- Electroless Nickel Plating

- Not Provided

-

T Dimension Specifying Method

- T Configurable Type

- T Fixed Type

-

Head Height T(mm)

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- Same day

- 10 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

Can stopper bolts catch lateral impacts?

-

Answer:

Not all stop bolts are suitable for lateral impact. Most stop bolts have an external hex for assembly. This may damage the surface of the components to be stopped due to its edges. We recommend stopper blocks as the side stoppers. MISUMI offers them in a wide variety of materials such as metal, plastic and rubber.

-

Question:

Why is the stopper bolt coloured?

-

Answer:

The stop bolt is dyed on one side, since the usable area was hardened by a tempering process. This should make the stop bolt more resistant to wear. Accordingly, this is not a colouring or painting, but a tempering colour that is created in metals by heating.

-

Question:

Where can the stopper bolt be installed?

-

Answer:

MISUMI offers suitable threaded stopper blocks for the fastening of stop bolts. The blocks can be mounted on a base plate and the stop bolts can be screwed into it.

-

Question:

How resistant are the stopper bolts with dampers?

-

Answer:

The stop bolts with polyurethane (PUR) are abrasion-resistant and have a high mechanical strength. Further properties and stabilities can be found in the PDF Properties of Polyurethane.

Variation of this product

| Part Number |

|---|

| SSTEH13 |

| SSTEH13A |

| SSTEH13B |

| SSTEH14 |

| STEHN7 |

| STEHN8 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Standard Shipping Days ? | RoHS | Tip O.D. (mm) | Material | Hardness | Surface Treatment | T Dimension Specifying Method | Head Height T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

4.81 € | 1 | Available |

Same day

Stock | 10 | 13 | [Stainless Steel] EN 1.4037 Equiv. | 50 - 55HRC | Not Provided | T Fixed Type | 5 | |

7.47 € | 1 | Available |

Same day

Stock | 10 | 13 | [Stainless Steel] EN 1.4037 Equiv. | 50 - 55HRC | Not Provided | T Fixed Type | 8 | |

7.70 € | 1 | Available |

Same day

Stock | 10 | 13 | [Stainless Steel] EN 1.4037 Equiv. | 50 - 55HRC | Not Provided | T Fixed Type | 8 | |

6.96 € | 1 | Available |

Same day

Stock | 10 | 14 | [Stainless Steel] EN 1.4037 Equiv. | 50 - 55HRC | Not Provided | T Fixed Type | 5 | |

3.17 € | 1 | Available |

Same day

Stock | 10 | 7 | [Steel] EN 1.7220 Equiv. | 46 - 50HRC | Electroless Nickel Plating | T Fixed Type | 5 | |

3.29 € | 1 | Available |

Same day

Stock | 10 | 8 | [Steel] EN 1.7220 Equiv. | 46 - 50HRC | Electroless Nickel Plating | T Fixed Type | 5 |

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)