Single Axis Actuators(With or without retainer:N/A)

| Shipping Days |

|

|---|

?* Information on days to ship and prices

-

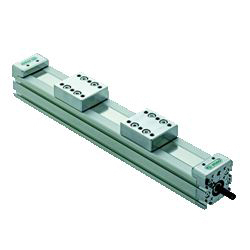

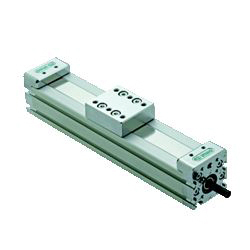

Actuator KR26

THK

An actuator with a compact and high-stiffness structure that integrates an LM guide, ball screw, and support unit, making it ideal for high-precision positioning.

[Features]

・ In addition to the standard specifications, the manufacturer will semi-order 5 highly requested customs, and will promptly procure and ship after ordering.

[5 custom made]

・ Dowel holes: Dowel holes are provided for alignment during assembly. It is also useful for preventing misalignment and reproducibility when replacing products.

・ Positioning Metal Bolt: Install the positioning metal bolts for origin alignment during assembly. It is also useful for reproducibility of the origin position when replacing the motor.

・ Sub-table side greasing hole: By processing a grease hole on the side of the sub table and attaching a grease fitting, greasing is possible without removing the cover.

・ AP-C processing: Surface treatment (THK, AP-C treatment) is applied to improve corrosion resistance.

・ AFF grease for clean environment: Encloses clean environment-friendly grease (THK, AFF grease) to suppress dust generation.

[Selection of sensors and sensor rails]

・ Please refer to the selection list on the "Product Information" tab.- 2D / 3D CAD data available

Configure nowMin. Shipping Days : 23 Days -

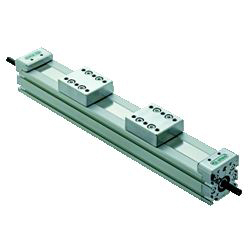

Actuator Unit (Opening and Closing Type)

IMAO CORPORATION

The main body combines stable sliding with T-grooves on three faces for easy mounting, achieving the optimal cross-section shape with maximum strength. The slide mechanism uses materials with excellent abrasion resistance and self-lubrication, and is usable long-term for loads from top, bottom, left, and right.- Volume Discount

- 2D CAD data available

Configure nowStarting from∗ : 443.64 € Min. Shipping Days : 8 Days *Unit price with basic configuration

-

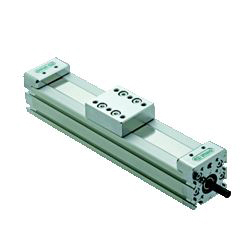

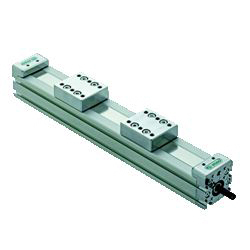

Actuator KR45H

THK

With a compact and highly stiff structure that integrates the LM guide, ball screw, and support unit, 5 semi-custom made actuators ideal for high accurate positioning are available.

[Features]

[5 custom made]

・ Dowel Holes: Dowel holes are provided for alignment during assembly. It is also useful for preventing misalignment and reproducibility when replacing products

・ Positioning metal bolt: Positioning metal bolts are installed for origin alignment during assembly. It is also useful for reproducibility of the origin position when replacing the motor

・ Sub-table side greasing hole: By processing a grease hole on the side of the sub table and attaching a grease fitting, greasing is possible without removing the cover

・ AP-C processing: Surface treatment (THK, AP-C treatment) is applied to improve corrosion resistance

・ AFF grease for clean environment: THK and AFF grease are sealed for a clean environment to suppress dust generation

[Selection of sensors and sensor rails]

・ Please refer to the selection list on the "Product Information" tab- 2D / 3D CAD data available

Configure nowMin. Shipping Days : 23 Days -

Actuator KR20

THK

With a compact and highly stiff structure that integrates the LM guide, ball screw, and support unit, 5 semi-custom made actuators ideal for high accurate positioning are available.

[Features]

[5 custom made]

・ Dowel Holes: Dowel holes are provided for alignment during assembly. It is also useful for preventing misalignment and reproducibility when replacing products

・ Positioning metal bolt: Positioning metal bolts are installed for origin alignment during assembly. It is also useful for reproducibility of the origin position when replacing the motor

・ Sub-table side greasing hole: By processing a grease hole on the side of the sub table and attaching a grease fitting, greasing is possible without removing the cover

・ AP-C processing: Surface treatment (THK, AP-C treatment) is applied to improve corrosion resistance

・ AFF grease for clean environment: THK and AFF grease are sealed for a clean environment to suppress dust generation

[Selection of sensors and sensor rails]

・ Please refer to the selection list on the "Product Information" tab- 2D / 3D CAD data available

Configure nowMin. Shipping Days : 23 Days -

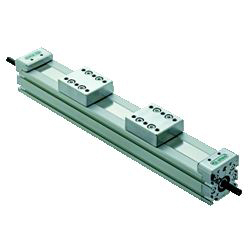

Actuator Unit (Opening and Closing Type)

IMAO CORPORATION

The main body combines stable sliding with T-grooves on three faces for easy mounting, achieving the optimal cross-section shape with maximum strength. The slide mechanism uses materials with excellent abrasion resistance and self-lubrication, and is usable long-term for loads from top, bottom, left, and right.- Volume Discount

- 2D CAD data available

Configure nowStarting from∗ : 442.70 € Min. Shipping Days : 26 Days *Unit price with basic configuration

-

Actuator Unit (Link Type)

IMAO CORPORATION

The main body combines stable sliding with T-grooves on three faces for easy mounting, achieving the optimal cross-section shape with maximum strength. The slide mechanism uses materials with excellent abrasion resistance and self-lubrication, and is usable long-term for loads from top, bottom, left, and right.- Volume Discount

- 2D CAD data available

Configure nowStarting from∗ : 263.85 € Min. Shipping Days : 26 Days *Unit price with basic configuration

-

Actuator KR30H

THK

With a compact and highly stiff structure that integrates the LM guide, ball screw, and support unit, 5 semi-custom made actuators ideal for high accurate positioning are available.

[Features]

[5 custom made]

・ Dowel Holes: Dowel holes are provided for alignment during assembly. It is also useful for preventing misalignment and reproducibility when replacing products

・ Positioning metal bolt: Positioning metal bolts are installed for origin alignment during assembly. It is also useful for reproducibility of the origin position when replacing the motor

・ Sub-table side greasing hole: By processing a grease hole on the side of the sub table and attaching a grease fitting, greasing is possible without removing the cover

・ AP-C processing: Surface treatment (THK, AP-C treatment) is applied to improve corrosion resistance

・ AFF grease for clean environment: THK and AFF grease are sealed for a clean environment to suppress dust generation

[Selection of sensors and sensor rails]

・ Please refer to the selection list on the "Product Information" tab- 2D / 3D CAD data available

Configure nowMin. Shipping Days : 23 Days -

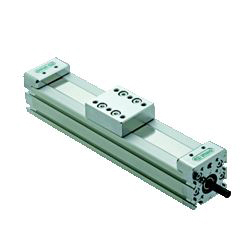

Actuator Unit

IMAO CORPORATION

The main body combines stable sliding with T-grooves on three faces for easy mounting, achieving the optimal cross-section shape with maximum strength. The slide mechanism uses materials with excellent abrasion resistance and self-lubrication, and is usable long-term for loads from top, bottom, left, and right.- Volume Discount

- 2D CAD data available

Configure nowStarting from∗ : 261.10 € Min. Shipping Days : 8 Days *Unit price with basic configuration

| Brand |

|---|

| Product Series |

| CAD |

| Starting from∗ |

| Min. Shipping Days |

| Main Body/Peripheral Components |

| Nominal (Height) |

| Accuracy |

| Table |

| Lead(mm) |

| Motor Mounting Posture |

| Cover |

| Grease |

| The presence or absence of motor |

| With or w/o Lubrication Units |

| With or without retainer |

| The shaft diameter of a ball screw(φ) |

| Table length L1(mm) |

| Table width W1(mm) |

| Amplifier Voltage |

| Brand | THK | IMAO CORPORATION | THK | THK | IMAO CORPORATION | IMAO CORPORATION | THK | IMAO CORPORATION |

|---|---|---|---|---|---|---|---|---|

| Product Series | ||||||||

| CAD |

|

|

|

|

|

|

|

|

| Starting from∗ | - | 443.64 € *Unit price with basic configuration Volume Discount | - | - | 442.70 € *Unit price with basic configuration Volume Discount | 263.85 € *Unit price with basic configuration Volume Discount | - | 261.10 € *Unit price with basic configuration Volume Discount |

| Min. Shipping Days | 23 Days | 8 Days | 23 Days | 23 Days | 26 Days | 26 Days | 23 Days | 8 Days |

| Main Body/Peripheral Components | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body |

| Nominal (Height) | 26 | 58 | 45 | 20 | 58 | 58 | 30 | 58 |

| Accuracy | Standard Grade | - | Standard Grade | Standard Grade | - | - | Standard Grade | - |

| Table | Long 1 pc. / Long 2 pc. | Long 2 pc. | Long 1 pc. / Long 2 pc. / Short 1 pc. / Short 2 pc. | Long 1 pc. / Long 2 pc. | Long 2 pc. | Long 1 pc. | Long 1 pc. / Long 2 pc. / Short 1 pc. / Short 2 pc. | Long 1 pc. |

| Lead(mm) | 2 ~ 6 | 3 | 10 ~ 20 | 1 ~ 6 | 3 | 3 | 6 ~ 10 | 3 |

| Motor Mounting Posture | Straight / Folding back | Straight | Straight / Folding back | Straight / Folding back | Straight | Straight | Straight / Folding back | Straight |

| Cover | N/A / Available | Available | N/A / Available | N/A / Available | Available | Available | N/A / Available | Available |

| Grease | Standard / Low Dust Generation | Standard | Standard / Low Dust Generation | Standard / Low Dust Generation | Standard | Standard | Standard / Low Dust Generation | Standard |

| The presence or absence of motor | No (Built-in by the customer) | No (Built-in by the customer) | No (Built-in by the customer) | No (Built-in by the customer) | No (Built-in by the customer) | No (Built-in by the customer) | No (Built-in by the customer) | No (Built-in by the customer) |

| With or w/o Lubrication Units | N/A | - | N/A | N/A | - | - | N/A | - |

| With or without retainer | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

| The shaft diameter of a ball screw(φ) | 8 | - | 15 | 6 | - | - | 10 | - |

| Table length L1(mm) | 47.4 ~ 64 | 55 | 43.5 ~ 108 | 33.2 ~ 46 | 55 | 55 | 39.5 ~ 74.4 | 55 |

| Table width W1(mm) | 31 ~ 62 | 49 | 53 ~ 104 | 23 ~ 52 | 49 | 49 | 38 ~ 80 | 49 |

| Amplifier Voltage | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

Loading...

Filter by:

-

Main Body/Peripheral Components

- Main Body

- Peripheral Part

-

Nominal (Height)

-

Accuracy

-

Table

-

Lead(mm)

-

Motor Mounting Posture

-

Cover

-

Grease

-

The presence or absence of motor

-

With or w/o Lubrication Units

-

With or without retainer

-

The shaft diameter of a ball screw(φ)

-

Table length L1(mm)

-

Table width W1(mm)

-

Amplifier Voltage

Brand

CAD data type

-

- 2D

- 3D