- inCAD Library Home

- > No.000061 Retaining Mechanism

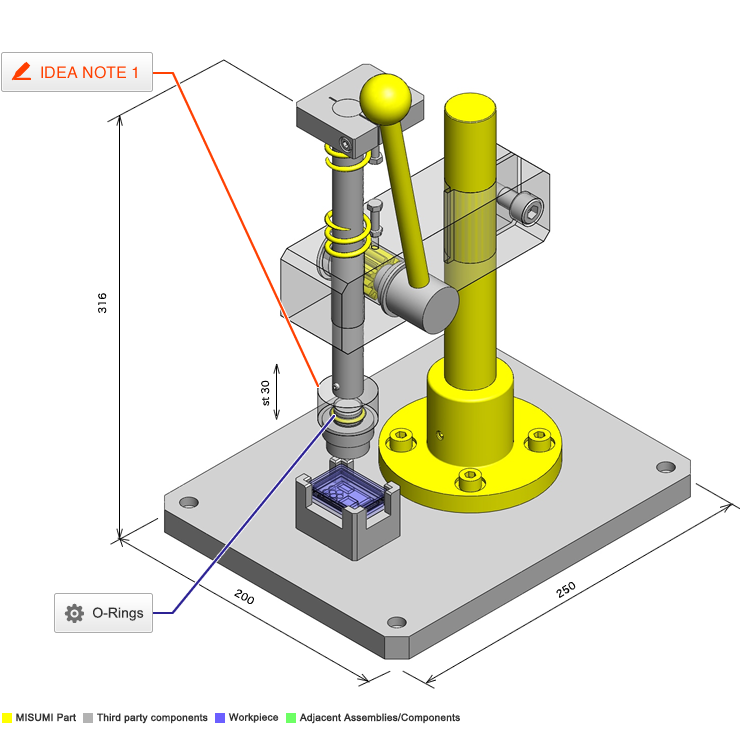

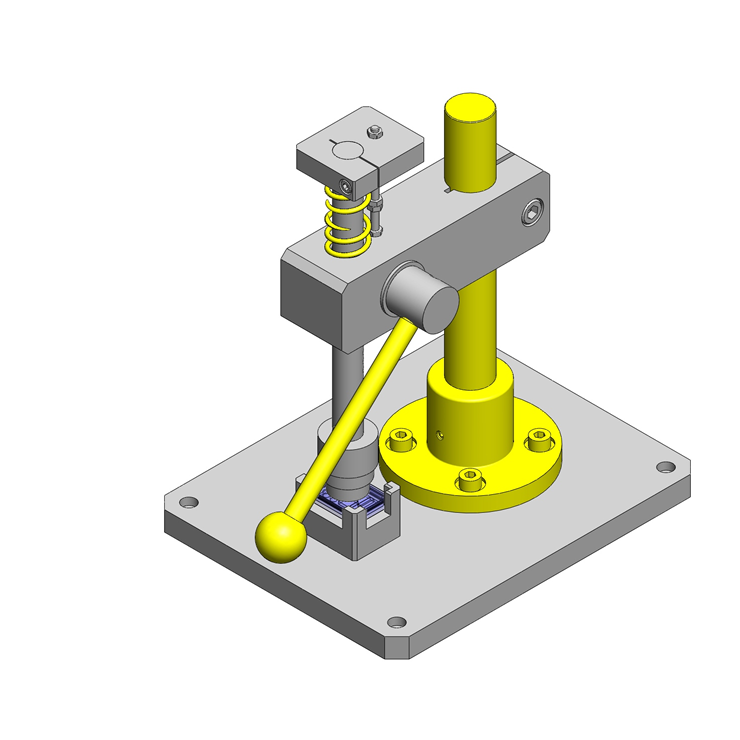

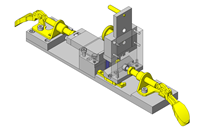

No.000061 Retaining Mechanism

50

50

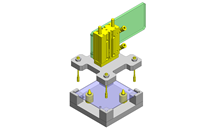

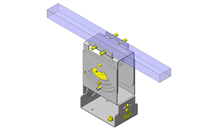

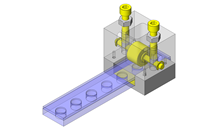

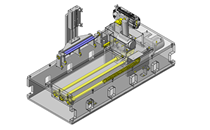

An O-ring is used for part retention.

Related Category

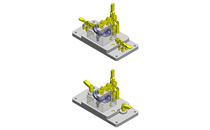

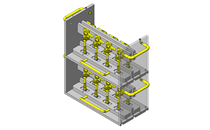

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

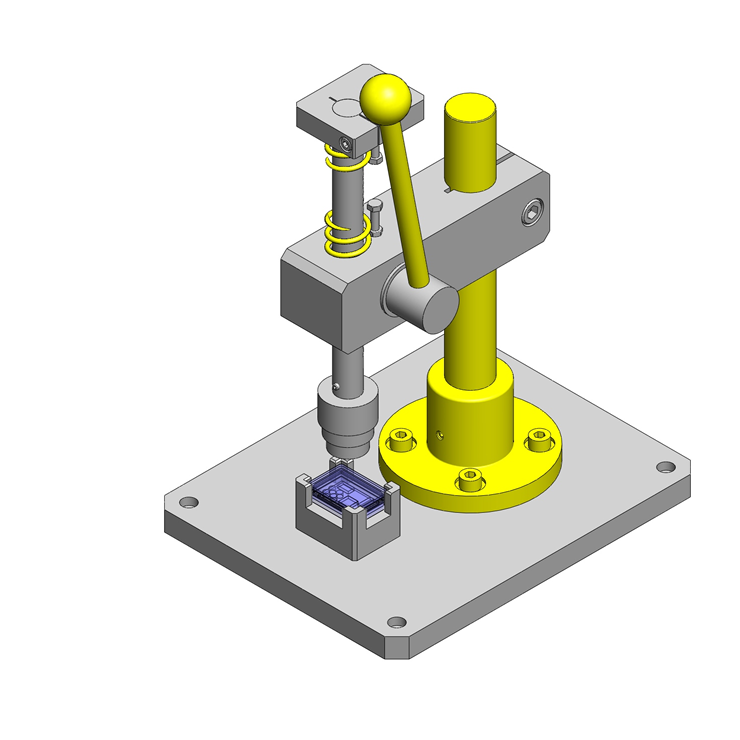

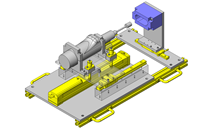

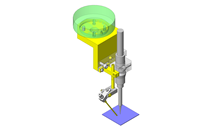

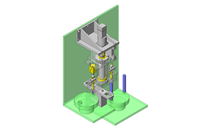

- A process where a cap is press-fit into a plastic casing.

Points for use

- Manual operation for small-quantity production.

Target workpiece

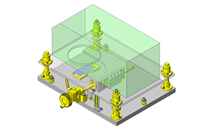

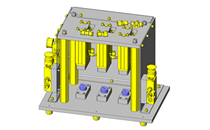

- Plastic cap

- Approximate workpiece size: 40 x 29 x 12mm

Design Specifications

Operating Conditions or Design Requirements

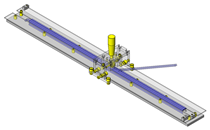

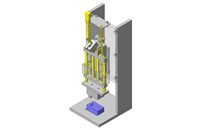

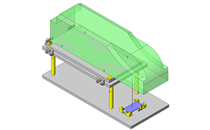

- External dimensions: W200 x D250 x H316mm

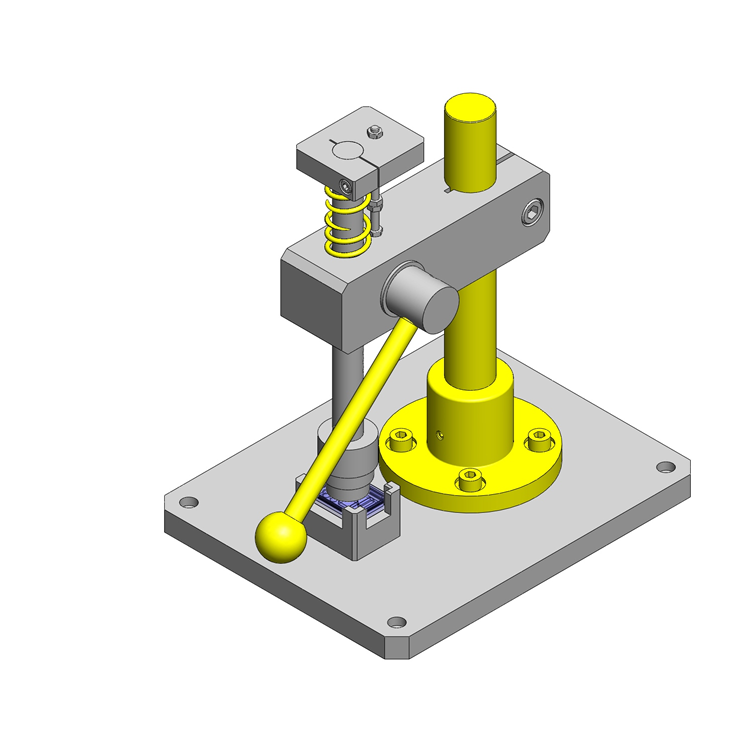

- Press fit stroke: 30mm

Required Performance

- Pushing force: 50N or more

- Operating load: 10N or less

Selection Criteria for Main Components

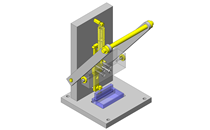

- Device mounting stand

- Select an economical shaft with a large diameter.

Design Evaluation

Verification of main components

- Verify that the cap pressing force meets the required operating load.

- Relationship between handle operating load and pushing force

- Conditional values:

Pinion pitch circle radius rm = 24mm = 0.024m

Operating load Fs N

Pushing force F N = 50N

Pinion center - Operation point R m = 160mm = 0.16m - F N = Fs x R/r

Operating load Fs = F / R x r Thus, Fs = 50 / 0.16 x 0.024 = 7.5N

⇒Meeting "Necessary operating load of 10N or less."

- Conditional values:

Other Design Consideration

- For most O-ring applications, the groove shapes conform to JIS standards. However, different shapes are used for this application.

Explore Similar Application Examples

Page

-

/

-