- inCAD Library Home

- > No.000265 O-Ring Insertion Jig

No.000265 O-Ring Insertion Jig

30

30

Simple and accurate O-ring insertion

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

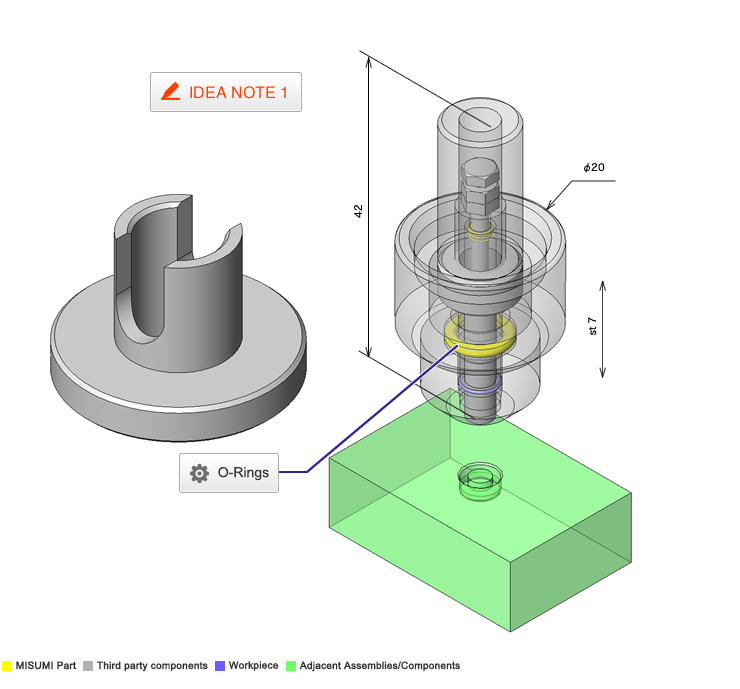

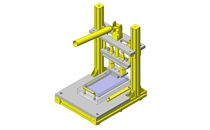

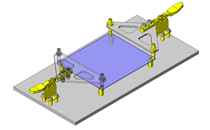

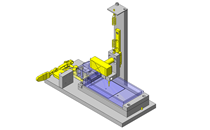

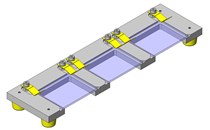

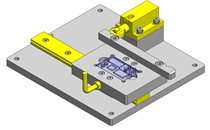

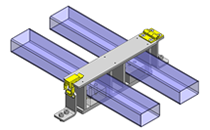

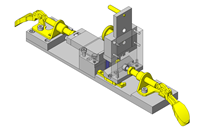

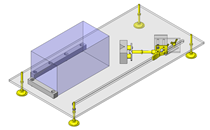

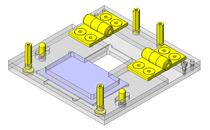

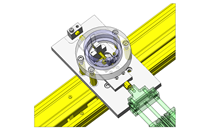

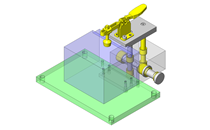

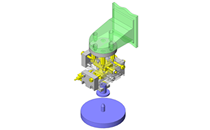

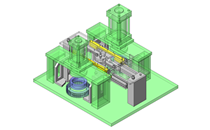

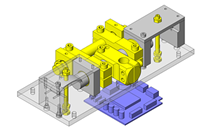

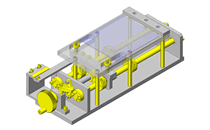

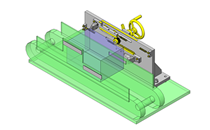

- The device in this application example consists of the insertion jig body (right side of figure) and the stand (left side of figure).

- O-ring setting

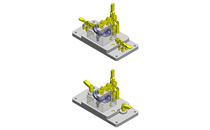

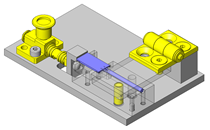

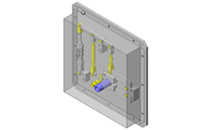

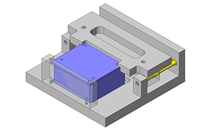

With the outermost sleeve of the jig body removed, set up the jig body in an opposite orientation to that shown in the figure on the left in the stand. The pin in the center has a dual structure. Set the workpiece (O-ring) on the inner pin and fit the removed outer sleeve back on. - Insertion positioning

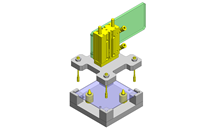

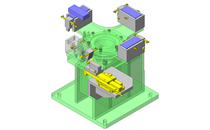

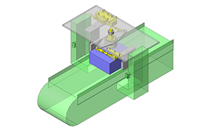

Orient the center pin fit with the O-ring downward (state shown in the figure on the left) and butt the jig against the insertion position of the assembly counterpart (green). Also butt the end of the outer sleeve against the assembly counterpart. - Insertion of O-ring

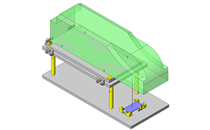

When the cylindrical part shown at the center in the figure on the left is pressed with the hand, the outer part of the dual structure pin at the center slides and pushes the O-ring out. In the jig, a cylindrical nut is located below the cylindrical part and the push stroke is adjusted according to the nut position. When the hand is released, the cylindrical part at the center returns to the original position due to the reaction force of the compression spring that is installed between the pin parts in the dual structure.

Points for use

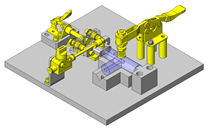

- Manual Operation

Applied to a portion where it is not possible to accurately incorporate an O-ring using your hands.

Target workpiece

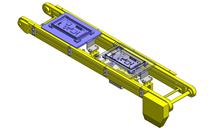

- Shape: O-ring (rubber)

- Size: inner diameter Ø3 x t0.5mm

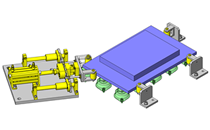

Design Specifications

Operating Conditions or Design Requirements

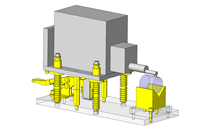

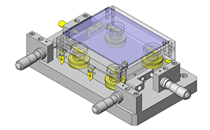

- Insertion stroke: 7mm

- Outer dimensions: Ø20 x H42mm

Required Performance

- Positioning accuracy: ±0.2mm

- Assumed load: 0.75N

Selection Criteria for Main Components

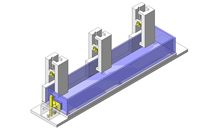

- The O-ring insertion guide is made of MC nylon.

- The insertion pin is made of EN 1.4301 Equiv. and precisely finished.

Design Evaluation

Verification of main components

- Confirmation of load of used spring

- Weight of parts to be returned: M = 14g

Friction coefficient between O-ring and pusher pin: f1 = 40g

Friction coefficient between inner guide and pusher pin: f2 = 10g

Required spring load: F

= M + f1 + f2

= 14 + 40 + 10

= 65g

Spring constant: K = 10g/mm

Free length: 20mm

Set length: 8.2mm

Spring set load: P = 10 x (20 - 8.2)

= 10 x 11.8

≒120g

Therefore, P > F.

- Weight of parts to be returned: M = 14g

Other Design Consideration

- The dimensions of the jig part are determined by knowing the accuracy of the product using the O-ring.

- Friction is reduced at the O-ring insertion guide.

Explore Similar Application Examples

Page

-

/

-