- inCAD Library Home

- > No.000058 Rotating table

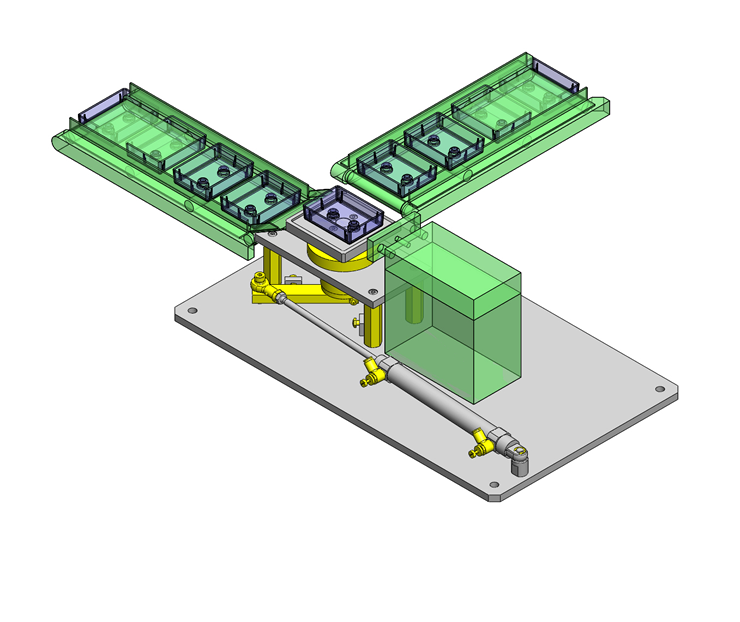

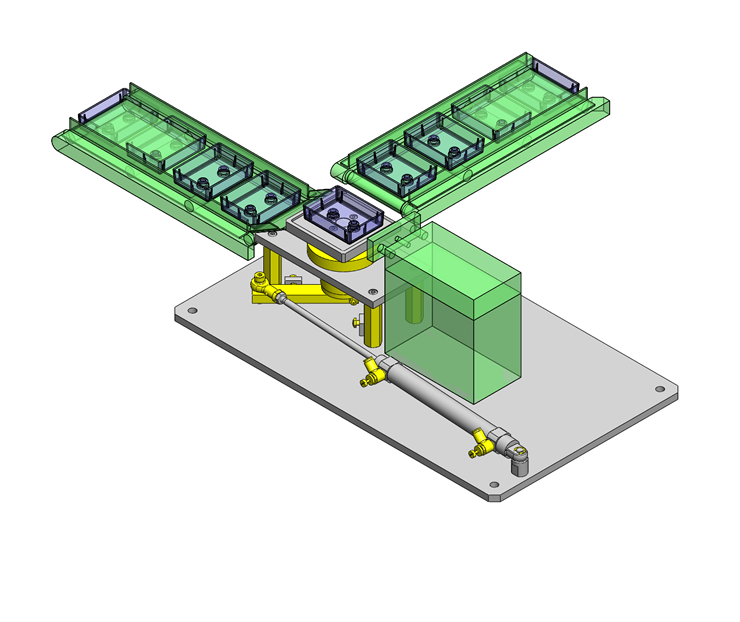

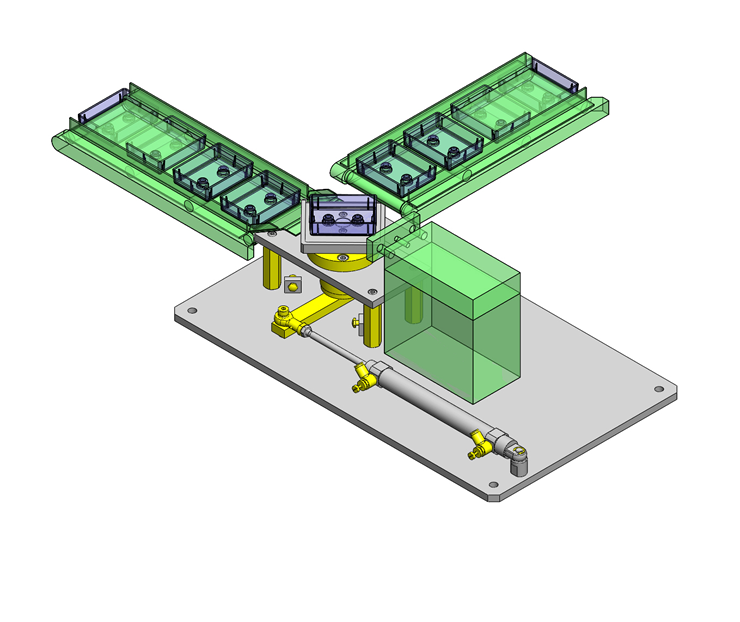

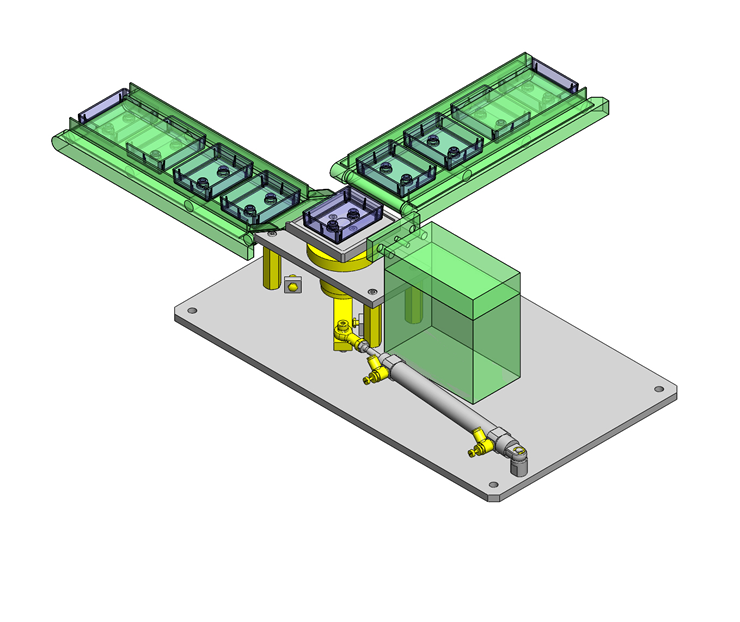

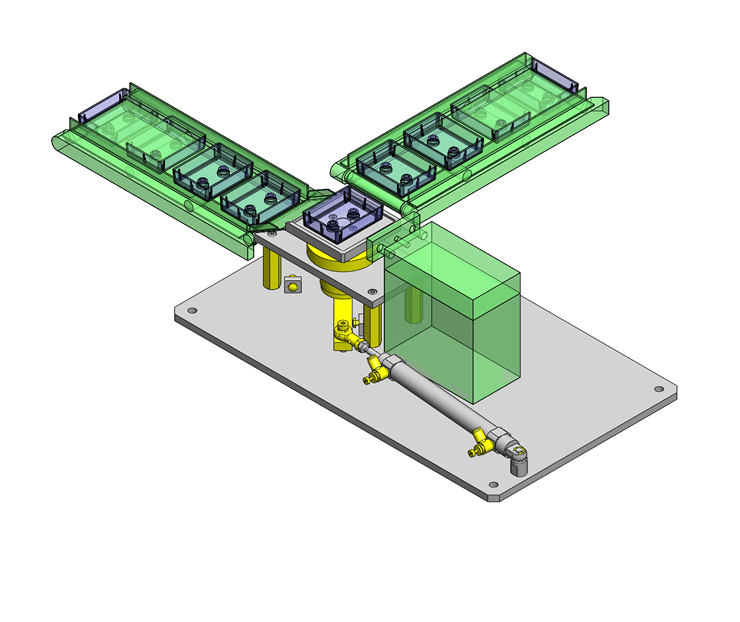

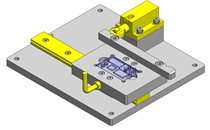

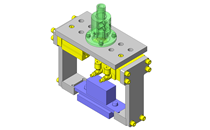

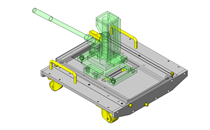

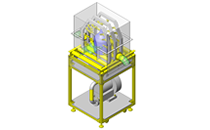

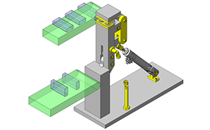

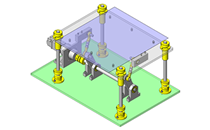

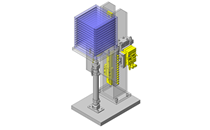

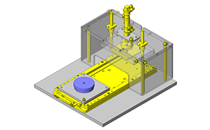

No.000058 Rotating table

31

31

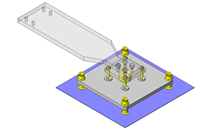

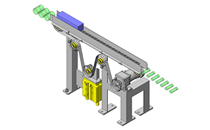

A rotating table with a linkage mechanism

Related Category

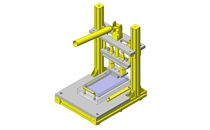

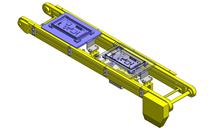

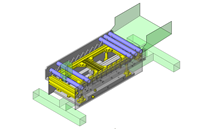

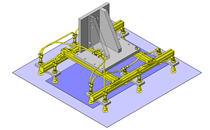

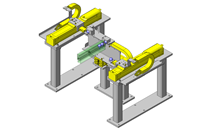

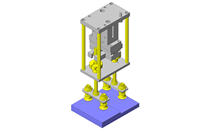

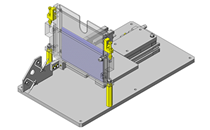

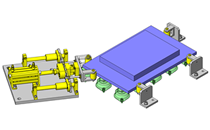

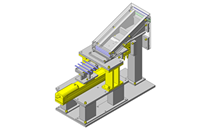

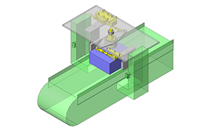

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

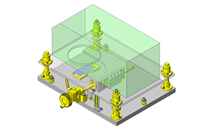

Purpose

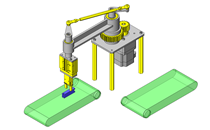

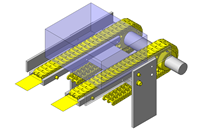

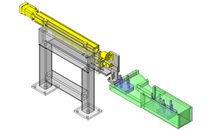

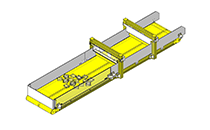

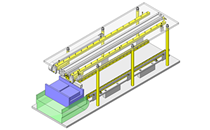

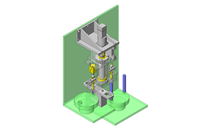

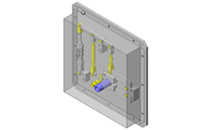

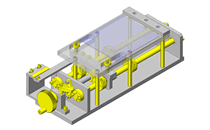

- Rotate workpieces 90 degrees using an air cylinder and a linkage system.

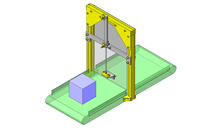

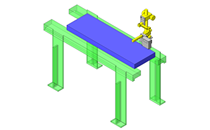

Target workpiece

- Plastic case.

- Approx. size: 60 x 80 x 20mm

Design Specifications

Operating Conditions or Design Requirements

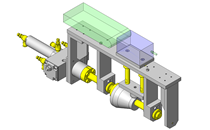

- External dims.: W320 x D550 x H129mm

Required Performance

- Workpiece weight: 0.1kg

Selection Criteria for Main Components

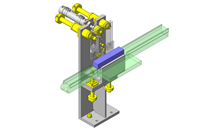

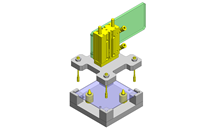

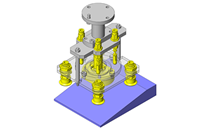

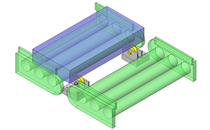

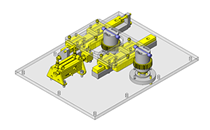

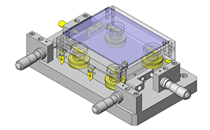

- Bearing with housing

- A bearing with housing is used to achieve smooth rotary motion.

Design Evaluation

Verification of main components

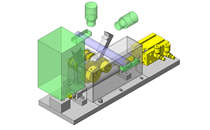

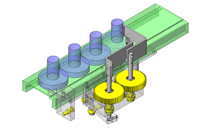

- The selection criteria for the cylinder are the workpiece load and the required stroke.

- Cylinder bore selection

- Conditional value:

Workpiece weight MW = 0.1kg

Table weight MT = 7.9kg

Bearing friction coefficient µ = 0.05

Gravitation acceleration g = 9.8m/s²

Operating pressure P = 0.4 MPa

Operating load F = µMg, F = 0.05 x (0.1 + 7.9) x 9.8 = 3.92N

If safety ratio is 5, select F0 = 3.92 x 5 = 19.6N or more.

Cylinder bore D0 = √(1.274 x F0 / P) thus, D0 = √(1.274 x 19.6 / 0.4) = 7.9mm

Therefore, the cylinder bore dia. should be 7.9mm or larger.

- Conditional value:

- Cylinder stroke selection

- Conditional values:

Distance from rotation center to cylinder rod end (Operating radius) r = 100mm

Operating angle θ = 90°

Length of hypotenuse a = 2 x r x sin (θ / 2) thus a = 2 x 100 x 0.707 = 141.4mm

Therefore, the stroke should be 141.4mm or larger.

- Conditional values:

- Selection results

- Cylinder bore --- Ø20mm, Stroke --- 150mm

T-shaped clevis type is selected for rocking mechanism.

- Cylinder bore --- Ø20mm, Stroke --- 150mm

Other Design Consideration

- Swing angle is adjusted with locating bolt as a stopper.

Explore Similar Application Examples

Page

-

/

-